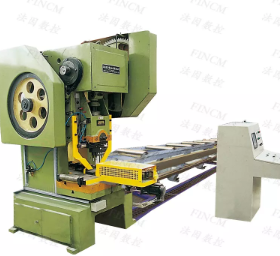

Technical specification of AP16A-8

Item | Name | Value |

Dimension of punching angle steel

|

| 40×40×3- 125×125×8mm The maximum angle raw material length is 8m |

Maximum diameter of punching |

| φ25.5mm |

Number of punching tools |

| 2 |

Punching hole’s back mark value |

| When angle dimension is ≥ 40~63mm, the back mark is ≥ 20mm When angle dimension is ≥ 70~100mm, the back mark value is ≥ 32mm When the angle dimension is ≥ 110~125mm, the center distance is ≥ 42mm |

Minimum end distance of punching hole to the material end |

| 25mm |

Servo motor power | X-axis (feeding length stop) | 1.5KW |

Y axis (change back mark value) | 1.0KW |

Product Features

Wide Punching Capacity

It supports a range of angle steel dimensions, from 40×40×3mm to 125×125×8mm, with a maximum raw material length of 8 meters. The punching machine is capable of punching holes with a maximum diameter of 25.5mm, offering flexibility for different types of projects and materials.

Adjustable Precision for Enhanced Accuracy

The system includes an adjustable back mark value based on the angle dimension, which ranges from 20mm to 42mm depending on the steel angle. This level of precision ensures that hole placements meet exact requirements, even for complex or custom materials.

High-Powered Servo Motor Drive

Equipped with a 1.5KW servo motor for the X-axis (feeding length stop) and a 1.0KW servo motor for the Y-axis (adjusting back mark value), it ensures smooth, reliable, and efficient performance. The servo motor system contributes to quicker setup times and reduced cycle times, making it ideal for large production runs.

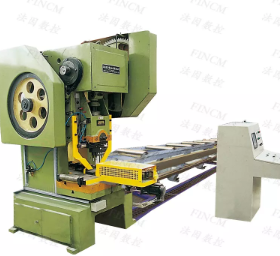

Product Advantages

Optimized for High-Volume Production

Designed for large-scale, precision-based manufacturing, this punching line delivers continuous, high-efficiency operations with minimal downtime. The reliable servo motor system and adjustable settings ensure that production runs smoothly without frequent interruptions.

Versatility for Various Materials and Sizes

With its ability to handle multiple angle steel dimensions and adjust hole placement based on angle, this punching machine caters to various industrial needs. Whether for standard or custom angle steel, it ensures a perfect punch every time.

Cost-Effective and Low Maintenance

The durable construction and efficient servo motor system help minimize wear and tear, reducing the need for frequent maintenance. This results in lower long-term operational costs and less downtime, improving the overall return on investment for the user.

Product Applications

Heavy-Duty Manufacturing

It is ideal for industries that require large-scale production of angle steel components, such as steel fabrication, construction, and structural engineering. Its versatile punching capabilities allow it to handle a wide range of material types and sizes, making it suitable for creating structural elements used in buildings, bridges, and industrial frameworks.

Custom Steel Processing

This punching line is perfect for custom steel processing projects, where precise hole placement is critical. It can be used in specialized applications, such as custom machinery, equipment frames, and other products that require tailored steel components, ensuring accuracy in every punch.

High-Volume Production Environments

Designed for continuous and efficient operation, this punching line excels in high-volume manufacturing settings, including automated metalworking plants. Its ability to punch large quantities of material quickly while maintaining precision makes it perfect for industries like automotive, machinery manufacturing, and metalworking, where speed and accuracy are essential for mass production.