Nominal force | 1000 KN |

Rated pressure of hydraulic system | 22Mpa |

Number of no-load running | 16 times/min |

Maximum shear angle profile range | Single blade cutting | 200x200x20mm(Q235-A, Max. Tensile Strengthσb≈410MPa) |

200x200x18mm(Q420, Max. Tensile Strengthσb≈680MPa) |

Shearing angle | 0°~45° |

Maximum cutting length | 300 mm |

| Square angle cutting | 200x200x16mm(Q235-A, Maximum tensile strengthσb≈410MPa) |

200x200x12mm(Q420, Maximum tensile strengthσb≈680MPa) |

Ambient temperature | 0℃~40℃ |

Motor power of hydraulic pump | 18.5kw |

Machine overall size | 2635mmx1200mmx2090mm |

Machine weight | about 6500kg |

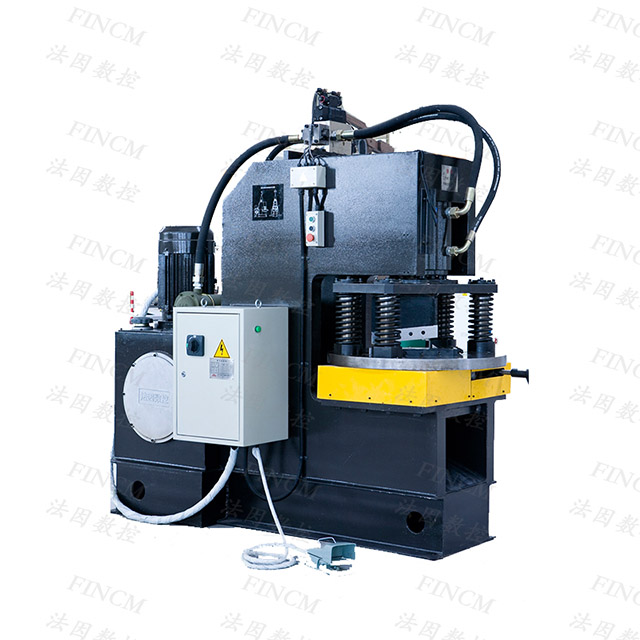

Product Overview

The ACH200 is a hydraulic-powered notching machine engineered for heavy-duty metal processing. With a nominal force of 1000 KN and a hydraulic system rated at 22 MPa, it efficiently handles materials up to 200×200×20 mm (Q235-A) and 200×200×18 mm (Q420) with tensile strengths of 410 MPa and 680 MPa, respectively . Its shearing angle range of 0°–45° and maximum cutting length of 300 mm make it versatile for both single-blade and square-angle cutting tasks. The machine operates at 16 no-load cycles per minute, ensuring high productivity even in demanding environments. Built with a 18.5 kW motor and designed for ambient temperatures of 0°C–40°C, the ACH200 combines power with reliability .

Product Features

High-Precision Cutting

The ACH200 achieves exceptional accuracy through its sliding rail-guided mold structure, which minimizes lateral loads and ensures precise alignment during cutting . This design supports both single-blade and square-angle cutting, with specifications tailored for Q235-A and Q420 steel profiles. For instance, it can notch 200×200×16 mm Q235-A and 200×200×12 mm Q420 with square angles, meeting the exacting standards of structural steel fabrication .

Hydraulic System Reliability

The machine’s hydraulic system, composed of an oil tank, motor, high/low-pressure pumps, and imported control valves (e.g., electromagnetic reversing valves), provides stable power transmission and long service life . The 22 MPa rated pressure ensures consistent performance across varying material thicknesses and hardness levels.

Versatile Operation

With adjustable shearing angles (0°–45°) and compatibility with multiple material grades, the ACH200 adapts to diverse applications. Its maximum cutting length of 300 mm accommodates large-scale projects, while the CNC control interface (as referenced in manufacturer details) enhances user flexibility and reduces manual adjustments .

Durable Construction

Constructed with a welded steel frame and heavy-duty components, the ACH200 weighs approximately 6500 kg and measures 2635×1200×2090 mm, ensuring stability during high-force operations . Its robust design withstands prolonged use in industrial settings, supported by a 1-year warranty on core components .

User-Friendly Design

The machine features intuitive controls and a foot pedal activation system, streamlining operator workflows. Additionally, its modular design facilitates maintenance, with clear access to hydraulic components and electrical systems .

Applications

Steel Fabrication: Ideal for manufacturing structural steel components (e.g., beams, brackets) for construction projects.

Energy & Mining: Supports the production of equipment for power plants, oil rigs, and mining machinery.

Transportation: Used in the fabrication of truck frames, railway components, and automotive parts.

Infrastructure: Enables the creation of bridge components, tower structures, and architectural steelwork.

General Manufacturing: Suitable for cutting and notching metal profiles in workshops producing machinery, tools, and industrial equipment .

FAQ

Q: What materials can the ACH200 process?

A: The ACH200 is optimized for Q235-A (tensile strength ≈410 MPa) and Q420 (tensile strength ≈680 MPa) steel profiles. It can also handle other alloys with comparable mechanical properties, though specific parameters may vary. Always consult the technical specifications for compatibility.

Q: What is the maximum thickness the ACH200 can cut?

A: For Q235-A, the maximum thickness is 20 mm (single blade) and 16 mm (square angle). For Q420, the maximum thickness is 18 mm (single blade) and 12 mm (square angle) .

Q: Does the ACH200 require specialized training to operate?

A: While basic training is recommended, the machine's intuitive controls and user-friendly interface allow operators to quickly adapt. The manufacturer provides on-site installation, commissioning, and training services to ensure proper setup and operation .

Q: What maintenance is required for the ACH200?

A: Routine maintenance includes checking hydraulic fluid levels, inspecting seals for leaks, and lubricating moving parts. The machine's imported components (e.g., valves, pumps) are designed for durability, reducing downtime. A 1-year warranty covers core components, and replacement parts are readily available .

Q: Can the ACH200 be customized for specific applications?

A: Yes. The manufacturer offers customizations such as voltage adjustments, logo engraving, and packaging options. Contact the supplier for detailed specifications tailored to your needs .