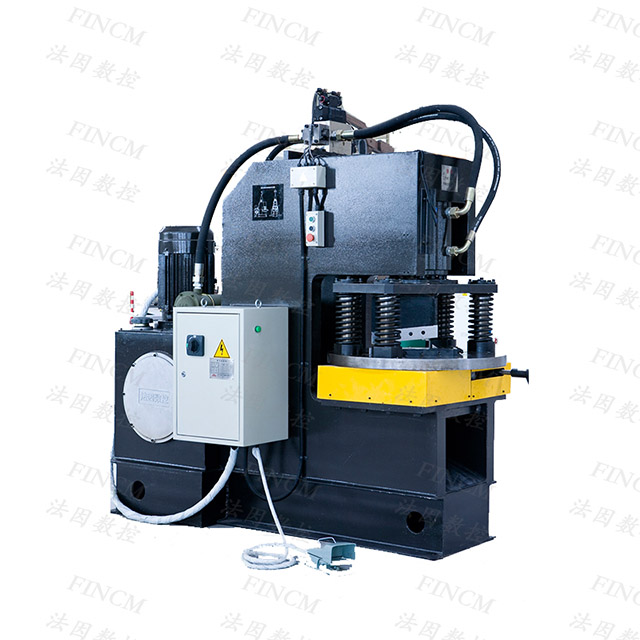

Nominal force | 1000 KN |

Rated pressure of hydraulic system | 22Mpa |

Number of no-load running | 16 times/min |

Maximum shear angle profile range | Single blade cutting | 200x200x20mm(Q235-A, Max. Tensile Strengthσb≈410MPa) |

| 200x200x18mm(Q420, Max. Tensile Strengthσb≈680MPa) |

| Shearing angle | 0°~45

|

| Maximum cutting length | 300 mm |

| Square angle cutting | 200x200x16mm(Q235-A, Maximum tensile strengthσb≈410MPa) |

| 200x200x12mm(Q420, Maximum tensile strengthσb≈680MPa) |

Ambient temperature | 0℃~40℃ |

Motor power of hydraulic pump | 18.5kw |

Machine overall size | 2635mmx1200mmx2090mm |

Machine weight | about 6500kg |

Product Overview

Its adjustable or fixed angle capabilities (typically 40°–135°) make it suitable for diverse applications, from creating 90° corners for metal boxes to custom angles for architectural components. With a focus on durability and user-friendly operation, these machines are engineered to meet the demands of high-volume manufacturing environments while maintaining strict quality standards.

Product Features

1. Hydraulic Power System

The hydraulic-driven mechanism ensures stable and controlled cutting force, with models offering nominal pressures between 1000kN and 1800kN. This system allows for adjustable stroke lengths and step-less pressure regulation, optimizing performance for different material thicknesses and cutting angles. Unlike manual or pneumatic alternatives, hydraulic operation reduces operator fatigue and enhances productivity, achieving up to 40 strokes per minute.

2. Precision Engineering

Equipped with high-quality guides and auto-adjusting blade gaps, these machines achieve cutting accuracy within ±0.05mm. The notching dies, made from SKD11 steel with heat treatment, ensure long-term wear resistance and consistent burr-free cuts. For adjustable models, manual or motorized angle adjustment (e.g., ±45°) allows operators to switch between angles quickly without complex recalibration.

3. Robust Construction

Constructed with welded steel frames and stress-relieved components, these machines offer exceptional rigidity and stability during operation. Features like reinforced worktables with T-slots and adjustable stops (e.g., 220mm maximum cutting length) facilitate precise workpiece alignment. Safety features, including transparent finger guards and emergency stop switches, comply with CE standards, prioritizing operator protection.

4. Versatile Configurations

Manufacturers often provide modular designs, allowing integration of additional functions such as punching, marking, or bending units. For example, the QJZ series supports mold changes to accommodate tasks like angle notching in steel towers or automotive part production. Models like the QA28Y offer variable angles (40°–135°), while fixed-angle machines like the QF28Y excel in high-speed 90° cutting for applications like metal box fabrication.

Applications

1. Construction Industry

Ideal for fabricating structural steel components, including beams, brackets, and trusses. The machine's ability to create precise angles (e.g., 90° for corner joints) streamlines the assembly of frameworks for buildings and bridges.

2. Automotive Sector

Used in manufacturing automotive parts such as chassis components, exhaust systems, and body frames. The adjustable angle feature supports complex geometries required for modern vehicle designs.

3. Pipe and Tube Fabrication

Efficiently notches pipes and tubes for applications like guardrails, handrails, and HVAC systems. Hydraulic models with auto-cooling systems ensure consistent performance during continuous operation on materials like stainless steel and aluminum.

4. Industrial Equipment

Critical for producing machinery parts, agricultural equipment, and industrial shelving. The machine’s durability allows it to handle heavy-duty materials while maintaining tight tolerances.

FAQ

Q: What is the maximum thickness this machine can process?

A: Depending on the model, hydraulic angle notching machines can handle materials up to 16mm in mild steel and 4mm in stainless steel. Always refer to the product specifications for exact limits.

Q: How often should the machine be maintained?

A: Routine maintenance includes checking hydraulic fluid levels, lubricating moving parts, and inspecting blade wear every 200–300 operating hours. Replace worn components (e.g., dies) as needed to maintain accuracy.

Q: Can the cutting angle be adjusted automatically?

A: Some advanced models offer motorized angle adjustment, while others require manual rotation of the notching die. Adjustable machines typically cover angles from 40° to 135°.

Q: Does the machine come with safety certifications?

A: Most manufacturers provide CE-certified models, ensuring compliance with European safety and environmental standards. Additional certifications may be available upon request.

Q: What materials are compatible with this machine?

A: Common materials include mild steel, stainless steel, aluminum, and copper. For specialized alloys, consult the manufacturer to confirm compatibility.