Model | TXZ20 |

Max size of work piece(mm) | Angles | L40х40х3 ~ L200х200х20 (especially zinc coated angles) |

round steel | below Φ150 |

channel steel | below [150 |

square steel | below □150 |

Times of stroke(min-1) | 25 |

Max straighten force (KN) | 1000 |

Working stroke(mm) | 20 |

Adjustable stroke(mm) | 100 |

Max close width (mm) | 220 |

Center height of slide rod (mm) | 200 |

Motor power (kW) | 7.5 |

Overall dimension L× W×H (mm) | 2318×1380×1340 |

Gross weight (KG) | 3500 |

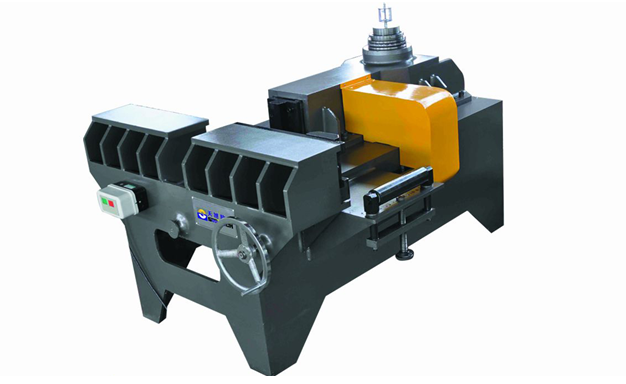

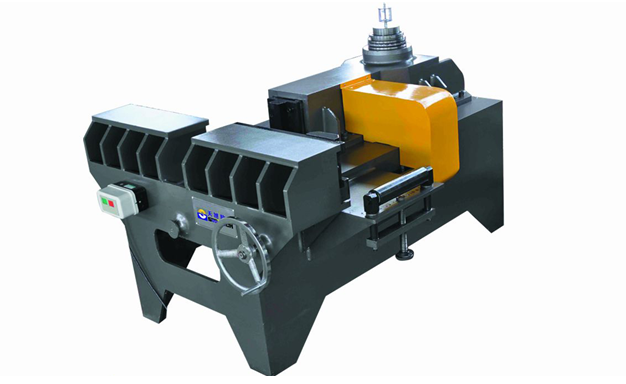

Product Overview

The TXZ20 Hydraulic Angle Straightening Machine is a high-performance industrial solution designed to correct deformations in various steel profiles, including angles, round steel, channel steel, and square steel. Engineered with precision and durability in mind, this machine is ideal for applications requiring accurate straightening of structural components in manufacturing, construction, and metalworking industries. With a focus on versatility and reliability, the TXZ20 handles workpieces up to L200x200×20 mm for angles, φ150 mm for round steel, [150 mm for channel steel, and □150 mm for square steel, making it suitable for a wide range of material sizes . Its robust design ensures consistent results even with zinc-coated angles, a common material in corrosion-resistant applications .

Product Features

High Straightening Force

The TXZ20 delivers a maximum straightening force of 1000 kN, enabling it to effectively correct stubborn bends and twists in heavy-duty steel profiles. This capability is critical for industries where structural integrity is non-negotiable, such as construction and automotive manufacturing.

Adjustable Stroke Design

With a working stroke of 20 mm and an adjustable stroke range of 100 mm, the machine allows operators to fine-tune the straightening process according to specific workpiece requirements. This flexibility minimizes material waste and ensures optimal results across diverse applications.

Efficient Hydraulic System

Powered by a 7.5 kW motor, the hydraulic system provides smooth, controlled force distribution. The machine’s 25 strokes per minute operational speed enhances productivity without compromising precision, making it suitable for high-volume production environments.

Compact and Rigid Construction

Measuring 2318×1380×1340 mm and weighing 3500 kg, the TXZ20 balances portability with structural stability. Its ergonomic design includes a 200 mm center height of the slide rod, ensuring easy integration into existing production lines.

Safety and Compliance

The machine incorporates industry-standard safety features, such as emergency stop mechanisms and protective guards, to safeguard operators during operation. It meets CE regulations for mechanical safety, ensuring reliable performance in regulated environments .

Applications

Manufacturing: Correcting deformations in automotive components, machinery frames, and conveyor systems. The machine’s precision ensures components meet tight tolerances for seamless assembly .

Metal Fabrication: Processing round, channel, and square steel for applications like furniture production, industrial shelving, and agricultural equipment. Its adaptability to various profiles reduces the need for specialized tools.

Energy and Infrastructure: Preparing steel profiles for power transmission towers and pipeline supports, where dimensional accuracy is critical for long-term structural stability .

FAQ

Q: What types of materials can the TXZ20 handle?

A: The TXZ20 is designed for angles (L40x40x3 to L200x200×20 mm), round steel (φ≤150 mm), channel steel ([≤150 mm), and square steel (□≤150 mm). It performs exceptionally well with zinc-coated angles, common in outdoor and corrosive environments .

Q: Is specialized training required to operate the TXZ20?

A: While basic technical knowledge is recommended, the machine’s intuitive interface and user-friendly controls minimize the learning curve. Proper training ensures optimal performance and adherence to safety protocols.

Q: How often should the TXZ20 be maintained?

A: Routine maintenance includes daily checks of hydraulic fluid levels, lubrication of moving parts, and inspection of wear components. A monthly inspection of the hydraulic system and structural integrity is advised to ensure long-term reliability .

Q: Can the TXZ20 be integrated into automated production lines?

A: Yes. Its compact design and standard interfaces allow seamless integration with CNC systems and material handling equipment, enhancing efficiency in automated workflows.

Q: What safety measures are in place?

A: The TXZ20 features emergency stop buttons, protective guards, and compliance with CE safety standards. Operators are advised to wear personal protective equipment (PPE) and follow all safety guidelines during operation .