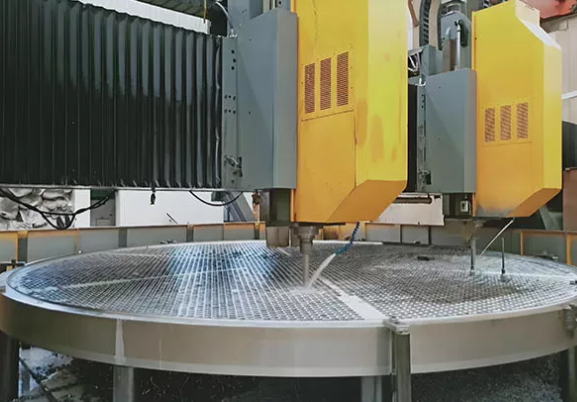

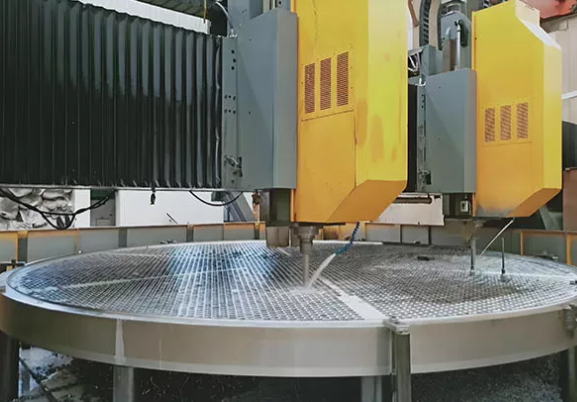

Product Features

Versatile Workpiece Compatibility

The FDZ15 is designed to handle a wide range of workpieces, including web heights from 200-1500mm, flange widths from 200-800mm, and flange thicknesses from 6-40mm. This flexibility makes it ideal for diverse H-beam assembly tasks in various industries, ensuring compatibility with different project requirements.

Efficient Assembly Speed

With an assembly speed of 0.5 to 6 meters per minute, the FDZ15 is built to optimize production time without compromising on quality. The adjustable speed allows users to tailor the process based on specific project needs, ensuring both efficiency and precision.

Reliable Power and Welding Capabilities

Equipped with dual 350A welding sources and a 7.5kW main power supply, the FDZ15 ensures powerful and consistent performance. The AC inverter used in the machine provides stable electrical control, enhancing welding accuracy and reducing energy consumption, making it reliable for high-volume production.

Product Advantages

High Flexibility for Different Projects

The FDZ15 offers exceptional versatility, accommodating a variety of workpiece sizes and configurations. Whether working on large or small H-beams, it adapts to different assembly requirements, making it a valuable asset for companies with varying production demands.

Enhanced Productivity

The combination of an efficient assembly speed (0.5 to 6m/min) and integrated input/output conveyors (2600mm x 3) enhances the workflow, minimizing downtime and increasing throughput. The streamlined process ensures that multiple steps are performed simultaneously, accelerating production without sacrificing quality.

Robust and Reliable

Built with durable components like an AC inverter and hydraulic systems, the FDZ15 guarantees long-lasting reliability. Its sturdy design ensures consistent performance even in harsh industrial environments, reducing maintenance needs and increasing the overall lifespan of the machine.

Product Specifications

Workpiece Web Height | 200-1500mm |

Flange Width | 200-800mm |

Flange Thickness | 6-40mm |

Assembly Speed | 0.5 - 6 meters per minute |

Workpiece Length | 4000mm - 15000mm |

Main Power | 7.5kW |

Welding Sources | Dual 350A |

Power Supply | Three-phase AC 415V, 50Hz |

Input/Output Conveyor Size | 2600mm x 3 |

Machine Type | H-beam Assembling Machine |

Hydraulic System | Yes |

Electrical Control System | Yes |

AC Inverter | Yes |

Dimensions (L x W x H) | Customizable (depends on workpiece size) |

Typical Applications

Construction and Structural Steel Manufacturing

It is widely used in the construction and steel fabrication industries for assembling H-beams, providing a reliable and efficient solution for creating strong structural components used in building frameworks and infrastructure projects.

Shipbuilding and Offshore Platforms

It is also a valuable asset in shipbuilding and offshore platform production, where precise assembly of H-beams is crucial. Its versatility and speed help streamline the manufacturing process for large-scale projects in harsh marine environments.

Heavy Machinery Production

In heavy machinery manufacturing, it plays a critical role in assembling the frame structures of equipment and machinery. Its robust design and high assembly speed allow for consistent production of large, durable components used in industrial machinery and equipment.