Product Overview

The BL1412S is a specialized 3-in-1 solution for iron tower manufacturing, integrating precision punching, clean shearing, and permanent marking in one compact system. It stands out for reducing processing time by 50% (vs. multi-machine setups), ±0.15mm operation accuracy, and compatibility with 63×63×5mm to 140×140×12mm angle steel—perfect for communication towers, transmission structures, and industrial frameworks.

Product Features

Tri-Function Processing System

The machine’s integrated design combines three operations in one workflow: punching with 1250 kN nominal force for holes from φ8mm to φ22mm in 12mm thick angle steel; shearing with 1850 kN shear force for square, angled, or mitred cuts; and marking with 900 kN force for permanent alphanumeric identification . This eliminates material handling between operations, reducing work-in-progress inventory and production bottlenecks.

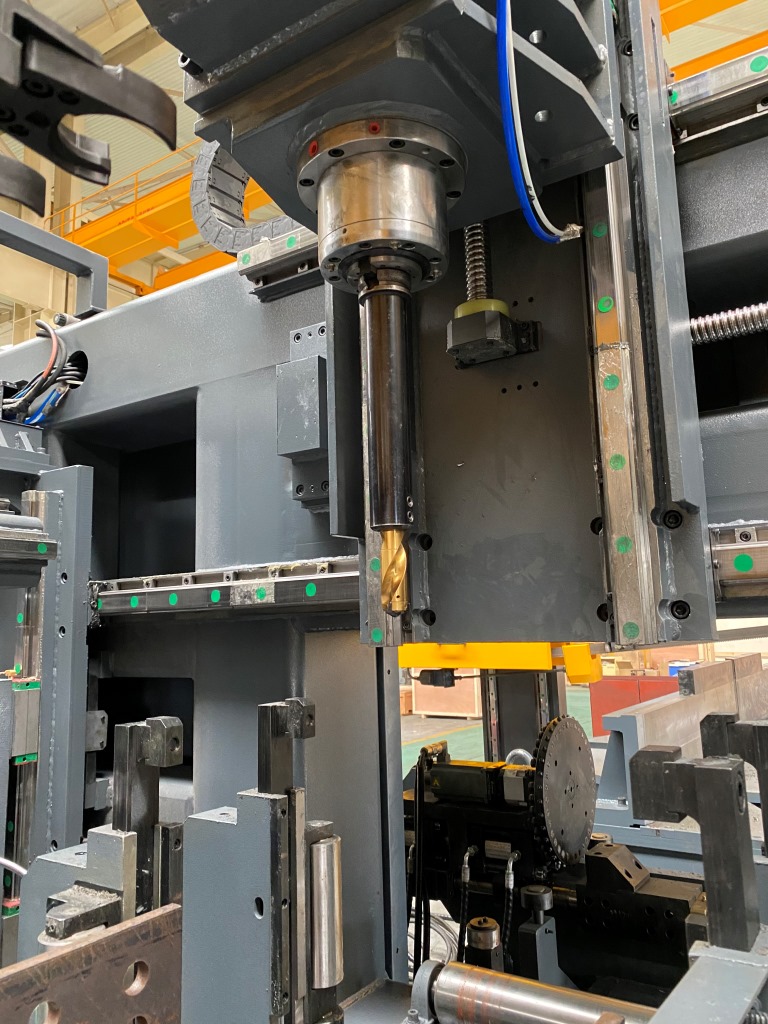

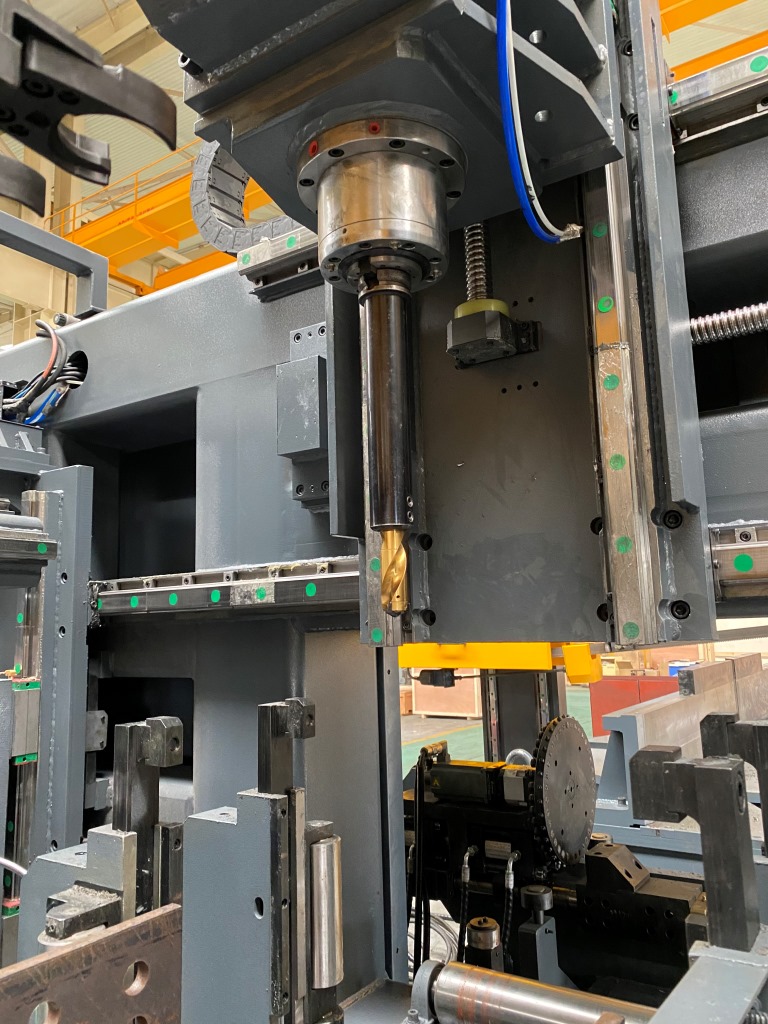

Precision Positioning Mechanism

A rack-and-pinion drive system powered by high-torque servo motors delivers exceptional positioning accuracy across the X and Y axes . The material feeding system achieves 35 m/min rapid traverse speed while maintaining positional precision, with a programmable backgauge that stores up to 200 positioning presets for common tower components.

Versatile Angle Compatibility

The BL1412S processes equal and unequal angle steel from 63×63×5mm up to 140×140×12mm, covering the most commonly specified sizes for communication and light transmission towers . The adjustable clamping system automatically adapts to different angle sizes, ensuring secure workpiece holding without deformation during processing.

Intelligent Process Control

An industrial-grade CNC controller with 9-inch touchscreen interface simplifies programming of complex sequences involving multiple punches, cuts, and marks. Operators can create programs via manual input, CAD file import, or parametric templates for standard tower components. The system includes real-time monitoring of punch and shear forces, with automatic adjustment of speed and pressure to prevent tool damage.

Applications

Communication Tower Manufacturing

The machine excels at processing angle steel components for 4G/5G cellular towers, microwave relay towers, and broadcast antenna structures. It precisely punches connection holes, shears to length, and marks component identifiers on tower legs, bracing members, and mounting brackets.

Transmission Line Structures

For medium-voltage power transmission towers and substation frameworks, the BL1412S produces angle steel components with consistent hole patterns and length dimensions, ensuring proper fit during field assembly.

Renewable Energy Support Structures

In solar panel mounting systems and small wind turbine towers, the machine processes angle steel components requiring precise hole positioning for structural integrity and alignment of renewable energy equipment.

Industrial Steel Framing

Beyond tower applications, it serves general fabrication needs for industrial shelving, mezzanine structures, and machine frames, where its combination of punching, shearing, and marking capabilities reduces production steps.

FAQ

What is the maximum processing speed for a typical tower component?

For a standard 100×100×8mm angle steel section requiring 4 holes and one shear cut, the machine completes the entire sequence in approximately 45 seconds, representing a 40% reduction compared to processing on separate machines.

How does the machine handle different angle steel grades?

The CNC system includes predefined parameter profiles for common tower steels including Q235, Q345, and ASTM A572. Operators can adjust punch force, shear speed, and marking depth for specialized materials up to 460 MPa tensile strength through the touchscreen interface.

What is the tool change time for different punch sizes?

The quick-change punch and die system allows tool changes in under 5 minutes without specialized tools. A tool storage magazine holds up to 8 common punch sizes, enabling quick recall during production runs.

What workshop space is required for installation?

The machine requires a footprint of 4.5m × 2.8m including material infeed and discharge areas. It should be installed on a level concrete foundation with minimum 150mm thickness to absorb vibration during heavy punching operations.

BL1412S CNC Punching, Marking and Cutting Machine for Angles

It is mainly used in the iron tower factory to manufacture angle steel components, and completes punching, fixed-length shearing and marking on the angle steel.

Technical specification of BL1412S

Angle size | ∠40*40*3~∠140*140*12mm |

Max. punching diameter | φ25.5mm(12mm thickness, Q345) |

Nominal punching force | 540KN |

Quantity of punching head per side | 2 |

The quantity of punching row per side | arbitrariness |

The quantity of character group | 4 groups |

Dimension of characters | 14×10mm(10) |

Max. length of the raw angle | 12m |

Cutting mode | Single-blade cutting |

Quantity of CNC axes | 3 |

The max. length of finished angle | 8m |

Hydraulic station cooling method | water cooling |

Angle feeding Speed | 40m/min, the efficiency is about 1000 holes/hour |

2.List of accessories and spare parts

No. | Code Name | Name | Qty. | Remark |

1 | BL14.5-42A | Punches for test run | 12 | Including the punches installed in the machine |

2 | BL14.5-43 | Female Dies for test run | 24 | Including the die installed in the machine |

3 | APM1412.6-7A | The Upper Blade | 1 | Including the blade installed in the machine |

4 | APM1412.6-7B | The Upper Blade | 1 |

|

5 | APM1412.6-8A | The Short nether Blade | 2 | Including the blade installed in the machine |

6 | APM1412.6-8B | The Long nether Blade | 2 | Including the blade installed in the machine |

7 | BL20.5-40A | Die carrier | 5 | Including the die carrier installed in the machine |

8 | BL20.5-38A | Poles of the Punches | 5 | Including the pole installed in the machine |

9 | BL14.5-41 | Nuts of the Punches | 5 | Including the nut installed in the machine |

10 | BL14.2-73 | The Upper Claw | 2 | Including the claw installed in the machine |

11 | BL14.2-74 | The Nether Claw | 2 | Including the claw installed in the machine |

12 |

| Springs of Every Parts | 1set |

|

13 |

| Pressure Oiler | 1 |

|

14 |

| Pneumatic gun | 1 |

|

15 |

| Common tools (including:full set of inner hexangular spanner, 500, 300, 150MM adjustable spanner, two solid spanner, a set of screwdriver) |

1batch |

|

16 |

| Standby paint | 2 kegs | 1 keg for main color and 1 keg for warning color |

17 |

| The Wrench for Tightening the Punches | 1 |

|

18 |

| Tools for Puff | 1 |

|

19 |

| The Drawing for wearing Parts | 2 volume |

|

20 |

| The Drawing for Maintenance | 2 volume |

|

21 |

| Quality Certificate, Packing List | 1 volume each |

|

22 |

| Instruction Manual (mechanical part, electric part, hydraulic part) | 2 volume each |

|

3.List of the Key Outsourced Components

NO | Name | Brand | Country |

1 | AC servo motor and servo driver | Panasonic | Japan |

2 | PLC | Mitsubishi |

3 | Double vane pump | Albert | USA |

4 | Electromagnetic unloading valve | ATOS/Yuken | Italy / Taiwan, China |

5 | Relief valve | ATOS/Yuken |

6 | Electromagnetic relief valve | ATOS/Yuken |

7 | Electro hydraulic directional valve | JUSTMARK |

Taiwan, China |

8 | Electromagnetic directional valve | JUSTMARK |

9 | Check valve | JUSTMARK |

10 | Air valve | AirTAC |

11 | Bus bar | AirTAC |

12 | Air value | AirTAC |

13 | Cylinder | SMC/CKD | Japan |

14 | Duplex | SMC/ CKD |

15 | Computer | Lenovo | China |