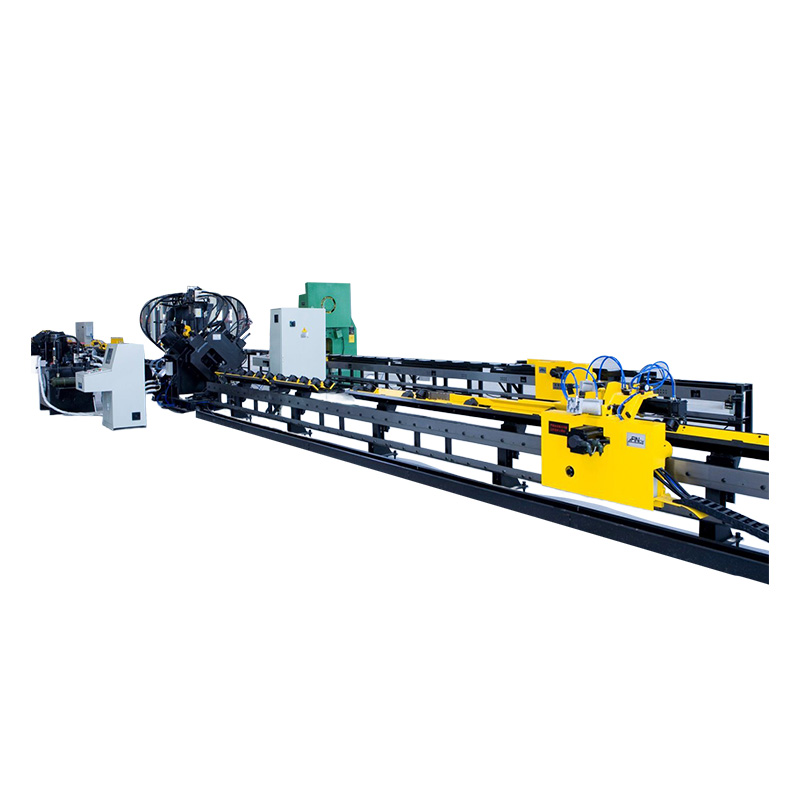

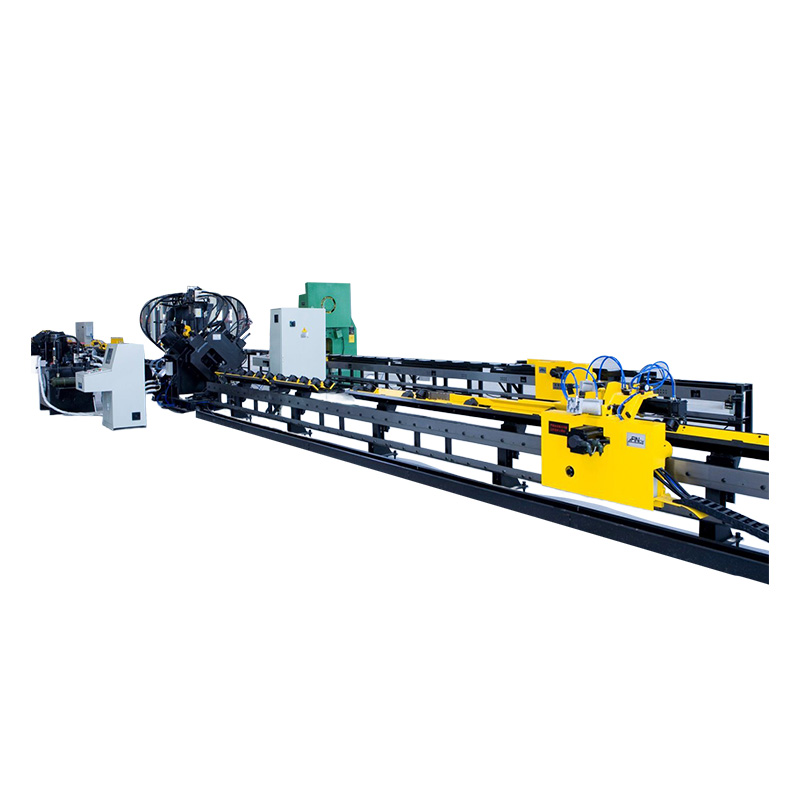

Product Overview

The APM2020 CNC Punch Shear is a specialized solution for steel tower manufacturers, integrating punching, shearing, and marking in one automated system. It processes 63×63×4mm to 200×200×20mm angle steel—common in communication towers, transmission structures, and small wind turbine supports. Its unique value lies in space efficiency (no need for multiple machines), 40m/min feeding speed, ±0.1mm positioning accuracy, and 1000 holes per hour throughput—ideal for small-to-medium tower fabrication facilities.

Product Features

Multi-Function Processing

The machine integrates three key operations: punching, shearing, and marking, eliminating the need for separate processing stations. The punching system delivers a nominal force of 1100 kN, capable of producing holes from φ10mm to φ25.5mm in 20mm thick angle steel (Q345 grade) . The shearing mechanism provides 1800 kN nominal force for clean, burr-free cuts, while the integrated marking station offers 1030 kN marking force for stamping part numbers and batch codes directly on workpieces .

High-Speed Production Capability

Equipped with a servo-driven feeding system, the machine achieves a material feeding speed of 40 m/min, enabling high-volume production with up to 1000 holes per hour under optimal conditions . The punching cycle time for a standard φ20mm hole in 16mm steel is approximately 3 seconds, while shear cycle time averages 6 seconds per cut, ensuring efficient processing of even complex tower components.

Precision Positioning System

The CNC control system delivers ±0.1mm positioning accuracy across the X and Y axes, ensuring consistent hole placement and cut lengths critical for tower assembly. A specialized angle centering mechanism automatically aligns workpieces along their centerline, maintaining positional accuracy regardless of angle size within the machine’s capacity range. The system stores up to 500 processing programs, allowing quick changeovers between different tower components.

User-Friendly Operation

The machine features a 10-inch touchscreen HMI with intuitive programming interface, supporting both manual parameter input and CAD file import. Operators can preview processing sequences in 2D before production, reducing setup time and material waste. Diagnostic functions provide real-time monitoring of machine status, with clear error messages to minimize troubleshooting time.

Applications

Communication Tower Manufacturing

The machine processes angle steel components for cellular towers, microwave communication towers, and broadcast antennas. Its precision ensures proper alignment of tower sections and antenna mounts, critical for structural stability and signal integrity.

Transmission Tower Components

In electrical infrastructure, it produces angle steel parts for medium-voltage transmission towers and substation structures, including bracing members, connection plates, and foundation brackets.

Renewable Energy Structures

The machine fabricates angle steel components for small wind turbine towers and solar panel support structures, where precise hole positioning is essential for modular assembly and environmental durability.

Light-Duty Structural Fabrication

Beyond tower applications, it serves general steel fabrication for industrial shelving, mezzanine structures, and light steel framing, offering versatility for custom fabrication projects.

FAQ

What is the maximum angle steel size the machine can handle?

The machine processes angle steel from 63×63×4mm up to 200×200×20mm, covering the full range of medium-sized angles used in light to medium-duty tower construction . This includes equal and unequal angle profiles within these dimensions.

How long does it take to change between punching and shearing operations?

The machine features a quick-change tooling system that allows operators to switch between punching dies and shear blades in under 8 minutes. Common tooling setups can be stored for quick recall, further reducing changeover time.

Can the machine process materials other than carbon steel?

While optimized for carbon steel (Q235, Q345), the machine can process mild alloy steels up to 350 MPa tensile strength with appropriate tooling. For higher strength materials, specialized tooling is recommended to maintain performance and tool life.

What safety features are included?

Safety features include interlocked protective guards, emergency stop buttons at multiple stations, and infrared sensors at material entry/exit points that halt operation if an obstruction is detected. The control system also monitors hydraulic pressure and motor load to prevent overload conditions.

What is the required workshop space and utilities?

The machine requires a footprint of approximately 5m × 3m including material handling space. It operates on a three-phase power supply (380V AC, 50Hz) with a 50A circuit and requires compressed air at 0.6–0.8MPa for clamping and ejection systems .

Angle size | 63×63×4-200×200×20 (Q345) |

Nominal Marking force | 1030 |

Nominal punching force | 1100 |

Nominal Shearing force | 1800 |

Maximum punch diameter (mm) | φ26 |

Maximum blank length (m) | 14 |

Maximum length of finished product (m) | 12 |

Number of print header groups | 4 |

Number of prefixes per group | 18 |

Prefix size (mm) | 14x10x19 |

Feeding speed of angle steel (M / min) | 60 |

Cooling mode | water-cooling |

Cut off mode | Double edged cutting |

Total power of equipment (kw) | 43 |

Machine dimension (m) | 32×7×3 |

Net weight (T) | About 18 |