Overview

Introduction to PUL1235/3 CNC 3-Sides Punching Machine

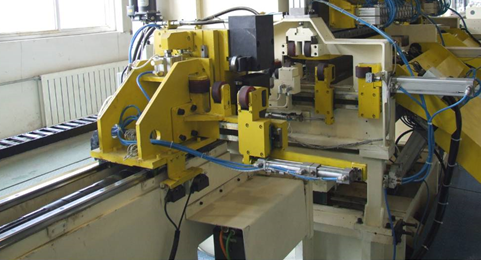

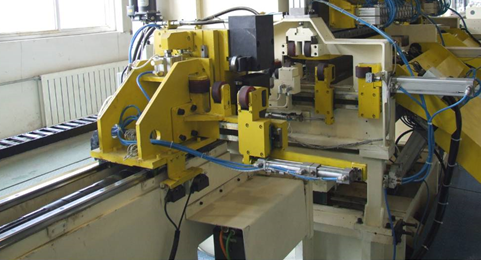

The CNC 3-sides punching machine PUL1235/3 is a dedicated automatic production line for truck chassis U-beams, engineered by FINCM to revolutionize longitudinal beam processing. Focusing on 3-sides punching of equal-cross-section U-beams, it integrates feeding, positioning, punching, and unloading into a seamless workflow. As a leader in truck chassis punching equipment, it combines high precision, efficiency, and flexibility to meet mass production and small-batch customization needs.

Core Advantages for Truck Chassis Production

This machine addresses key challenges in U-beam processing, such as low automation, inconsistent hole precision, and long setup times. By realizing full automation and high-precision control, it improves production efficiency by 50% and reduces labor costs, becoming a game-changer for commercial vehicle manufacturers.

Key Features & Benefits

Full-Automatic Production Line Integration

From magnetic feeding to automatic unloading, the entire process requires no manual intervention. The automatic punching line reduces human error, ensuring consistent quality across batches and shortening production preparation time.

High-Precision Punching & Hole Spacing Consistency

With X-direction hole spacing tolerance of ±0.3mm/2000mm (±0.5mm/12000mm) and Y-direction group hole tolerance of ±0.3mm, it delivers precise U-beam punching results. The high-precision Balluff linear sensors ensure stable positioning even for long workpieces.

Flexible Module Configuration for Versatile Needs

Equipped with 18 movable web modules, 21 main web modules (5×Φ25), and 6 fixed/movable flange modules, it supports punching diameters from plate thickness to Φ60mm (web) and Φ23mm (flange), adapting to diverse U-beam designs.

Exceptional Production Efficiency

For 12-meter U-beams with ~300 holes, the punching time is only 7 minutes. The high-speed X/Y axis movement (up to 30m/min) and parallel processing capability significantly boost throughput.

Reliable Loading & Unloading Mechanism

The magnetic feeding/unloading device (10 electromagnets, 2kN suction each) and 40m/min middle manipulator ensure smooth workpiece transfer, supporting stacking heights up to 500mm.

Core Components & Quality Assurance

World-Class Core Components

Key parts include Siemens ONE CNC system (Germany), Siemens servo motors (Germany), Balluff precision linear sensors (Germany), HIWIN linear guide rails (China Taiwan), and FESTO pneumatic components (Germany). These components ensure reliability and precision.

Rigorous Quality Inspection Standards

Each PUL1235/3 undergoes strict performance testing, including 100-hour continuous punching trials and precision verification. We adhere to ISO standards, with replaceable same-quality components guaranteed for supply stability.

Application Scenarios

Commercial Vehicle Chassis Manufacturing

Specialized in punching truck chassis longitudinal beams for light, medium, and heavy-duty trucks, supporting mainstream chassis designs.

Automotive Longitudinal Beam Production

Processes U-beams for bus, lorry, and special vehicle frames, meeting the industry’s high-strength and precision requirements.

Heavy-Duty Truck Frame Processing

Ideal for mass production of truck frames, ensuring consistent hole positions for assembly accuracy.

Custom U-Beam Component Fabrication

Adapts to small-batch, multi-variety production of custom U-beams, supporting new product development for automotive manufacturers.

Action Call & After-Sales Service

Get a Custom Quote Today

Ready to upgrade your truck chassis production line? Inquire now to get a tailored solution and competitive pricing. Share your U-beam specifications, and we’ll optimize the machine configuration for you.

Comprehensive After-Sales Support Package

We offer on-site installation, operator training, a 1-year warranty on key components, and global spare parts supply. Our technical team provides 24/7 online support to resolve issues promptly, ensuring uninterrupted production.

Data of U beam before punching | Data of U beam before punching | σb=510-890 MPa |

Length of U beam | 4000~ (+) |

Inside width of U beam web | 200-340 mm (+) |

U beam flange height | 60 (±) |

U beam thickness | 4-10 mm |

Fillet radius | R (+) |

Longitudinal straightness deviation of Web surface | 0.1%, ≤/ overall length |

Longitudinal flatness deviation of flange surface | /m, ≤/ overall length |

Maximum twist | / overall length |

Angle between flange and web | 90o±1 |

Data of U beam after punching | Punching diameter of Web | Maximum Φ 60mm. Minimum equals plate thickness |

Punching diameter of flange | Maximum Φ 23. Minimum equals plate thickness |

The minimum distance between the centerline of the hole on the web closest to the inner surface of the flange | 20mm when Hole diameter ≤ Φ 13mm 25mm when Hole diameter ≤ Φ 23 50mm when Hole diameter>Φ 23mm |

The minimum distance between the U beam inner side web surface and the centerline of flange hole | 25 mm |

The punching accuracy shall be controlled within the following range (except for the range of 200 mm at both ends) and the centerline distance accuracy between holes | Tolerance value of hole spacing in X direction: ± 0.3mm/2000mm; ±0.5mm/12000mm Tolerance value of group hole distance in Y direction:±0.3mm |

Accuracy of the Distance from hole centerline to the flange inner edge | ± |

Module position and punching travel of punching press | Movable web CNC punching press | 18 modules, straight line. |

CNC punching press for large web plate | 21 modules, straight line, 5 modules of Φ25. |

Fixed flange CNC punching press | 6 modules, straight line. |

Movable flange CNC punching machine | 6 modules, straight line. |

Punching travel of main machine |

|

Production Efficiency |

| When the length of the U beam is 12 meters and there are about 300 holes, the punching time is about 7 minutes |

Machine Overall Size | Length x Width x Height | about 36000mm x 8500mmx 4000mm. |

Loading and unloading trolley | Move travel | about 2000mm |

Move speed | about 4m/min |

Stacking height | about 500mm |

Magnetic In-feeding device / Magentic downloading device | Horizontal travel | about 2000mm |

Horizontal motor power | 1.5kW |

Vertical travel | about 600mm |

Vertical motor power | 4kW |

Number of electromagnets | 10 |

Electromagnet suction force | 2kN/each piece |

Infeeding Manipulator | Maximum speed | /min |

X-axis travel | about 3500mm |

Movable CNC Punching Press for web | Nominal force | 800kN |

Punch hole diameter types | 9 |

Module number | 18 |

X-axis travel | about 400mm |

X-axis maximum speed | 30m/min |

Y- axis travel | about 250 mm |

Y-axis maximum speed | 30m/min |

Maximum punch diameter | Φ23mm |

Main CNC Punching Press for web | Nominal force | 1700kN |

Punch hole diameter types | 13 |

Module number | 21 |

Y- axis travel | about 250mm |

Y-axis maximum speed | 30m/min |

Maximum punch diameter | Φ60mm |

Middle manipulator | Maximum speed | 40m/min |

X-axis travel | about 2000 mm |

Fixed Flange CNC punching press | Nominal force | 650kN |

Punch hole diameter types | 6 |

Module number | 6 |

Z-axis travel | about 100mm |

Z-axis maximum speed | 10 m/min |

Maximum punch diameter | Φ23mm |

Movable Flange CNC punching press | Nominal punching force | 650kN |

Punching hole diameter types | 6 |

Module number | 6 |

Y-axis travel | 160mm |

Y-axis maximum speed | 10 m/min |

Z-axis travel | about 100mm |

Z-axis maximum speed | 10 m/min |

Maximum punching diameter | Φ23mm |

Output material manipulator | Maximum speed | /min |

X axis travel | About 3500mm |

Hydraulic system | system pressure | 24MPa |

Cooling mode | Oil cooler |

Pneumatic system | working pressure | 0.6 MPa |

Electrical system |

| Siemens 840D SL |

No. | Name | Brand | Country | Remark |

1 | CNC Control System | Siemens ONE | Germany |

|

2 | Servo motor | Siemens | Germany |

|

3 | Precision linear sensor | Balluff | Germany |

|

4 | Hydraulic system | H+L | Germany |

|

5 | Other main hydraulic components | ATOS | Italy |

|

6 | linear guide rail | HIWIN | Taiwan, China |

|

7 | Wide guide rail | HPTM | China |

|

8 | Precision ball screw | I+F | Germany |

|

9 | Screw support bearing | NSK | Japan |

|

10 | Pneumatic components | SMC/FESTO | Japan / Germany |

|

11 | Single air bag cylinder | FESTO | Germany |

|

12 | Elastic coupling without backlash | KTR | Germany |

|

13 | Frequency converter | Siemens | Germany |

|

14 | computer | LENOVO | China |

|

15 | Drag chain | IGUS | Germany |

|

16 | Automatic lubrication device | HERG | Japan | Thin oil |

Note: The above is our fixed supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.

1).Power supply: 3 phase 5 lines 380±10%V 50±1Hz

(as per Brazil local voltage)

2).Compressed air pressure: ≥0.5MPa

3).Temperature: 0

4).Humidity: ≤75%