Product Features

High Punch Force

With a punch force of 1200kN, the PP123CNC Hydraulic Punching Machine delivers powerful and precise punching, capable of processing even tough and thick plates, ensuring high-quality results across various industries.

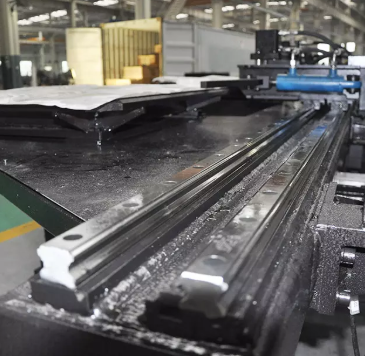

Wide Workpiece Compatibility

This machine supports plates up to 775 x 1500mm in size and thicknesses ranging from 5 to 25mm. Its ability to handle various material sizes makes it versatile and adaptable to different industrial needs, from small to medium-sized plates.

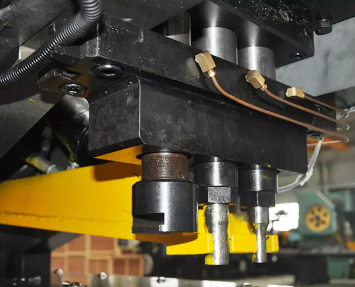

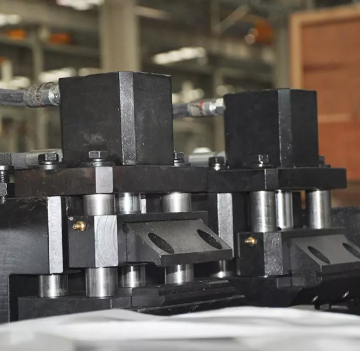

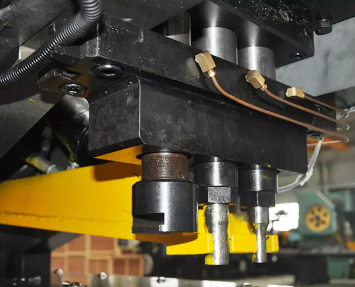

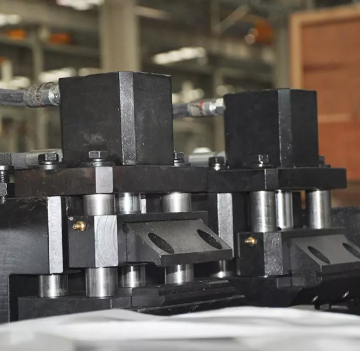

Multiple Die Stations

Equipped with 3 die stations, it allows for greater flexibility and operational efficiency. This feature significantly speeds up production times by enabling multiple tasks to be performed simultaneously, improving overall throughput.

Product Advantages

Increased Productivity

The machine’s high punch force and efficient design ensure that operations are completed faster and more accurately, maximizing productivity without sacrificing quality. The 3 die stations further enhance speed, making it ideal for high-demand production environments.

Precision and Accuracy

The PP123CNC ensures precision hole positioning after each clamping, reducing errors and material wastage. This level of accuracy is crucial for industries like steel structure and automobile manufacturing, where precision is key to maintaining quality standards.

Durable and Reliable

Built with high-quality materials and advanced technology, this machine is designed for long-lasting performance. Its robust motor and hydraulic system ensure consistent output, even in high-volume production settings, making it a reliable asset for continuous operations.

Product Specifications

| Specification | Details |

| Punch Force | 1200kN |

| Plate Size | Up to 775 x 1500mm |

| Plate Thickness | 5 to 25mm |

| Max Punch Diameter | 30mm |

| Die Stations | 3 |

| Motor Power | 15kW (Hydraulic pump), 2x2kW (Servo motors) |

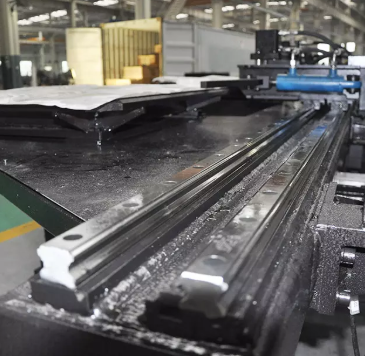

| Cooling Type | Water cooling |

| Total Power | 26kW |

| Machine Weight | 7500kg |

Product Applications

Steel Structure Manufacturing

Ideal for punching plates used in the construction of steel structures, ensuring precise and efficient hole placement for components like beams and columns.

Automobile Industry

Perfect for punching holes in automotive parts, such as chassis or body panels, where precision and speed are essential for high-quality production.

Metal Plate Processing

Suitable for a wide range of plate processing applications, including HVAC systems, electrical enclosures, and other industries requiring precise and efficient punching of metal plates.

PP123CNC Hydraulic Punching Machine for Plates

1. Technical specification of PP123:

Punch force | 1200kN |

Marking force | 1000kN |

Max. size of workpiece | 775×1500mm |

Thickness of workpiece | 5 ~ 25mm |

Max. punching diameter | Φ30mm Q235 σb≤420MPa φ30×25mm Q420 σb≤680MPa φ25.5×20mm |

No. of die station | 3 |

Min. distance between hole and plate edge | 25mm |

No. and Dimension of character | 16 (14×10mm) |

Motor power of hydraulic pump | 15kW |

The servo motor power of X and Y axes | 2×2kW |

The compressed air force ×discharging quantity | 0.5MPa×0.1m3/min |

Cooling type | Water cooling |

Total Power | 26kw |

Overall dimensions(L*W*H) | 3600*2800*1870mm |

Net weight of the machine | About 7500kg |

2. List of accessories and spare parts of PP123:

Serial No. | Code Name | Name | Quantity | Remark |

1 | PPHD123.2-2 | Character Box | 1 |

|

2 | BL2020.4-12 | Character for test run | 10 |

|

3 | PPHD123.2-3 | Mat dies | 1 |

|

4 | PPHD123.2-18 | die for test run | 9 | 16-8、16-12、16-16、20-8、20-12 20-16、24-8、24-12、24-16 |

5 | BL16.5-31A | Punches for test run | 6 | φ17.6(2)、φ21.6(2)、 φ25.6(2) |

6 | PPHD123.2-12 | plunger rod | 2 |

|

7 | PPHD123.2-13 | plunger rod for marking | 1 |

|

8 | PPHD123.18-3 | Punch nut | 3 | M48×1.5(1)、M39×1.5(2) |

9 | PP103A.5-2 | splint(the upper jaw) | 2 |

|

10 | PP103A.5-4 | distance plate(the nether jaw) | 2 |

|

11 | PP103A.2-21 | Wrench for Special Use | 1 |

|

12 |

| Tools for Nitrogen puffing | 1 |

|

3. List of the main outsourcing components of PP123:

No. | Name | Quantity | Country |

1 | AC Servo Motor | Panasonic | Japan |

2 | PLC | Mitsubishi |

3 | Electromagnetic unloading valve | ATOS/Yuken | Italy/Taiwan China |

4 | Relief valve | ATOS/Yuken |

5 | Electromagnetic directional valve | JUSTMARK | Taiwan China |

6 | Manifold plate | SMC/CKD | Japan |

7 | Air valve | SMC/CKD |

8 | Cylinder | SMC/CKD |

9 | Filter and Air Regulator service unit | Air TAC | Taiwan China |

10 | Computer | LENOVO | China |