Technical Specifications

Item | Unit | FRAS 6025 |

Cutting Capacity(N/mm²) | mm | 25 |

Cutting Length | mm | 6000 |

Variable Cutting Angle | mm | 0.5°-2.5° |

No. of Plate Holders | pcs | 30 |

No. of Stroke / min (SPM) |

| 5/10 |

Clamp Force | KN | 500 |

Cutting Force | KN | 1500 |

Backguage Stroke | mm | 1000 |

Main Motor | KW | 37 |

Machine Weight(Approx.) | Tons | 50 |

Working Height | mm | 1200 |

Machine Length | mm | 6830 |

Machine Width | mm | 2550 |

Machine Height | mm | 3200 |

Product Features

High Cutting Capacity and Length

The machine offers an impressive cutting capacity of 25 N/mm² and a cutting length of 6000 mm, making it ideal for large and thick plate cutting tasks across various industries.

Variable Cutting Angle

With a variable cutting angle ranging from 0.5° to 2.5°, it provides flexibility to accommodate different material thicknesses and shearing requirements, ensuring optimal results.

Reliable and Efficient Operation

Equipped with a powerful 37 kW motor, it delivers a cutting force of 1500 kN. The advanced NC controller (E21S) enhances operational control, making the machine both reliable and efficient during high-volume production.

Product Advantages

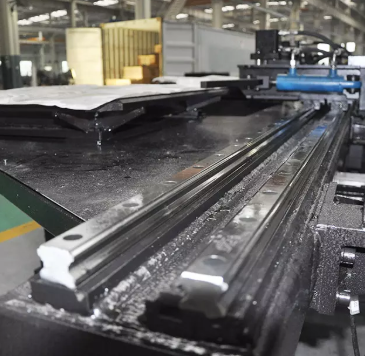

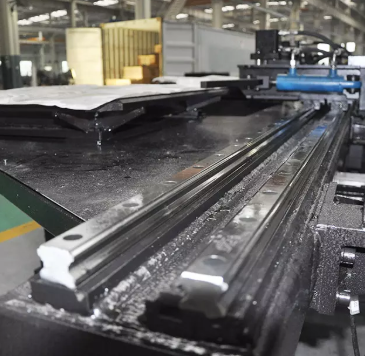

Enhanced Durability

The use of high-quality components, such as hard chrome rods and a ball screw for the back gauge, ensures long-lasting performance. This durability minimizes maintenance needs and reduces downtime.

Versatile and User-Friendly

The machine’s intuitive E21S NC controller simplifies operation, while the adjustable cutting angle and robust design allow it to handle a wide range of materials and cutting tasks with ease.

Heavy-Duty Performance

Built with a 50-ton weight and a powerful 37 kW motor, this machine excels in demanding applications, ensuring smooth and precise cutting under heavy-duty conditions, increasing overall productivity and reducing operational costs.

Product Usage Scenarios

Heavy-Duty Plate Cutting

This machine is ideal for industries such as construction, shipbuilding, and aerospace, where cutting thick and large metal plates is a regular task. Its 6000 mm cutting length and 25 N/mm² cutting capacity allow it to handle heavy-duty plate cutting with ease, ensuring precision even in the toughest materials.

High-Volume Manufacturing

In high-volume production environments, this machine excels in cutting large quantities of metal components quickly and consistently. Its powerful 37 kW motor and reliable hydraulic system enable it to maintain high performance over extended periods, reducing downtime and increasing overall production efficiency.

Custom Metal Fabrication

The hydraulic guillotine shearing machine is perfect for custom metal fabrication needs. Its adjustable cutting angles (0.5° to 2.5°) and versatility make it capable of cutting a wide range of materials with different thicknesses, ideal for industries like automotive, machinery manufacturing, and metalworking, where precision and adaptability are required for specialized parts.