Overview

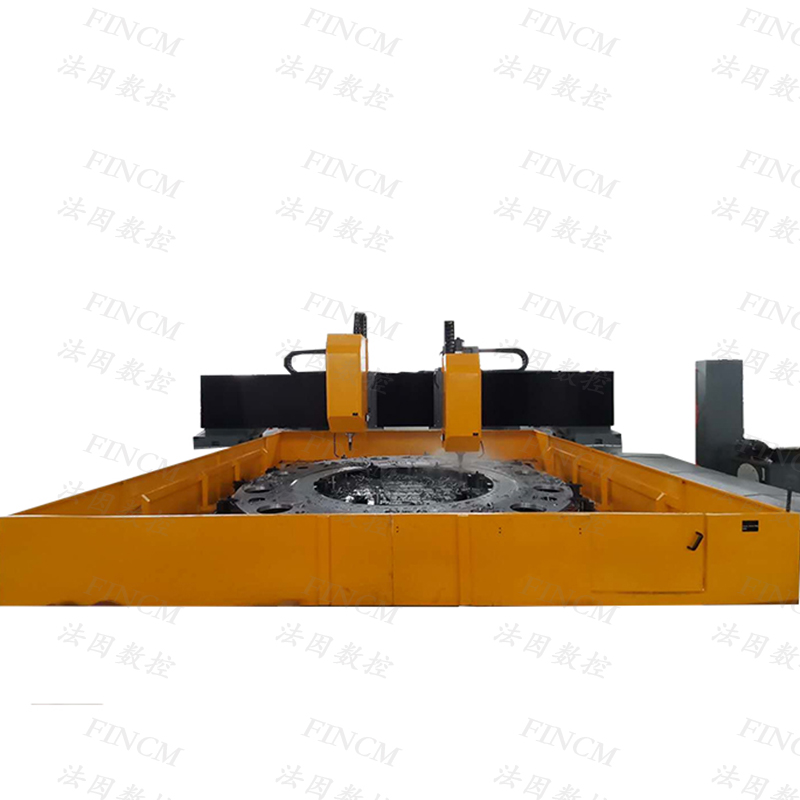

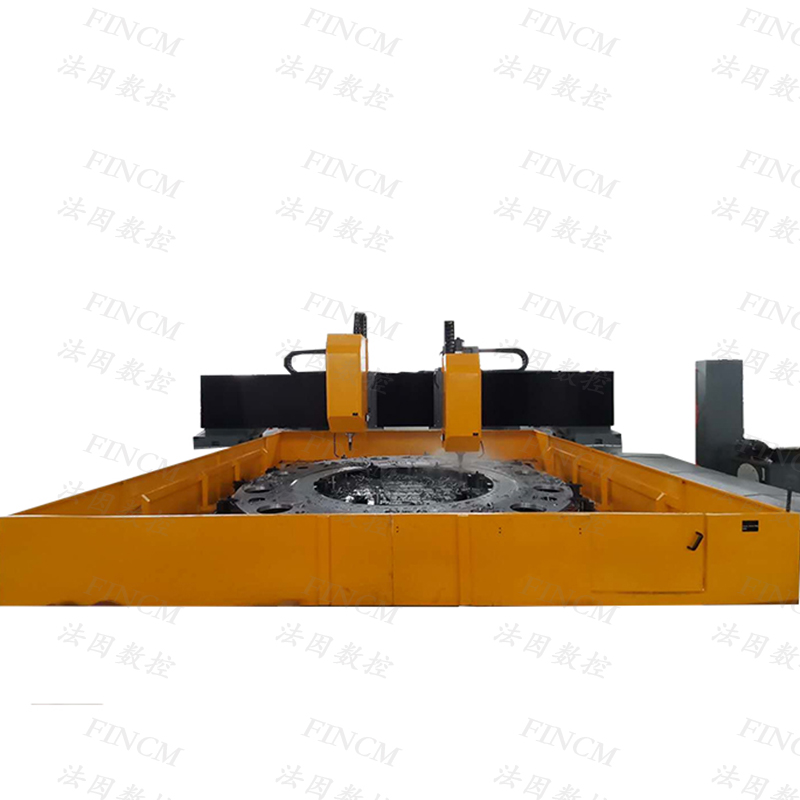

The Gantry Movable CNC Plate Drilling Machine PLM4040/2 is a high-performance industrial-grade machining solution designed for large-scale, high-precision processing of thick plates, tube sheets, and flange parts. Engineered with a robust gantry structure, this CNC drilling machine integrates multiple machining capabilities—including drilling, milling, grooving, chamfering, and light milling—delivering one-stop processing for complex workpieces. Ideal for industries requiring heavy-duty and precise plate machining, it eliminates the need for multiple equipment setups, significantly enhancing production efficiency while ensuring consistent quality.

Key Features & Benefits

Exceptional Machining Versatility

Equipped with dual drilling power heads, the PLM4040/2 supports multi-process integration for workpieces with diameters up to φ60mm. From standard drilling to precision milling and chamfering, it handles diverse machining needs in a single operation, reducing production cycles and labor costs.

Superior Precision & Repeatability

Boasting an X/Y-axis positioning accuracy of 0.08mm per full stroke and repeat positioning accuracy of 0.04mm, this machine ensures ultra-precise machining for critical components. The Siemens 828D CNC system enables precise program control, minimizing human error and guaranteeing consistent results across batches.

Heavy-Duty Load-Bearing Capacity

The machine’s workbench features a 3t/㎡ load-bearing capacity and a spacious 4500×4000mm size, easily accommodating large workpieces up to 4000×4000mm in length and width. Its durable structure supports plate thicknesses up to 250mm (scalable to 380mm), making it suitable for heavy-duty industrial applications.

Flexible Workpiece Adaptability

With adjustable spindle-to-worktable distances (280—780mm) and customizable machining parameters, the PLM4040/2 adapts to various workpiece thicknesses and material types. Whether processing carbon steel, alloy steel, or stainless steel, it maintains stable performance and machining quality.

Efficient Chip Removal & Cooling

Equipped with two flat-chain chip conveyors (1m/min speed) and an internal + external cooling system, the machine effectively removes chips during high-speed machining and prevents tool overheating. The cooling system’s 2MPa maximum pressure and 50L/min flow rate extend tool life and ensure machining precision.

Core Components & Quality Assurance

The PLM4040/2 relies on globally renowned components to ensure reliability and durability:

CNC System & Servo Motor: Siemens 828D CNC (Germany) and Siemens servo motors/drivers for precise motion control.

Linear Guide Rails: HIWIN/PMI (Taiwan, China) high-precision rails for smooth, low-wear axis movement.

Precision Spindle: KENTURN/SPINTECH (Taiwan, China) spindle for stable high-speed rotation.

Hydraulic & Pneumatic Parts: YUKEN/Justmark hydraulic valves (Japan/Taiwan, China) and high-quality air supply components.

Electrical Components: SCHNEIDER/ABB buttons and indicator lights (France/Germany) for safe, reliable operation.

All components undergo strict quality inspections, and the machine complies with international industrial standards, ensuring long-term stable performance in harsh working environments.

Application Scenarios

Pressure Vessel Manufacturing

Ideal for drilling and milling tube sheets and flanges in boilers, heat exchangers, and pressure vessels—critical for ensuring sealed performance and structural integrity.

Construction Machinery

Processes thick-plate components for excavators, cranes, and loaders, such as frame structures and connecting flanges, meeting high-strength and precision requirements.

Wind Power Equipment

Machines large flanges and base plates for wind turbine towers, supporting the renewable energy industry’s demand for heavy-duty, high-precision parts.

Heavy-Duty Equipment Frames

Used in manufacturing frames for industrial machinery, mining equipment, and marine vessels, where large-size, thick-plate machining is essential.

Action Call & After-Sales Service

Ready to elevate your heavy-duty plate machining efficiency? Inquire now for a customized quote or add the PLM4040/2 to your basket to secure availability. We offer comprehensive after-sales support, including:

Professional on-site installation and commissioning by certified technicians.

Detailed operator training for CNC programming, machine operation, and maintenance.

24/7 technical support via phone and email to resolve issues promptly.

Original spare parts supply (e.g., photoelectric edge finders, BT50 tool handles) for long-term machine upkeep.

Quality certificates and maintenance manuals to ensure compliance and easy management.

Maximum machining workpiece size | Length x width | 4000×4000 mm |

Maximum processed plate thickness | 250 mm,Scalable to 380mm |

Workbench | Workbench Size | 4500×4000 mm |

T-groove width | 28 mm |

load-bearing | 3t/㎡ |

Drilling power head | Maximum borehole diameter | φ60 mm |

Maximum aperture ratio | ≤10(Crown drill) |

Spindle speed | 30-3000 r/min |

Spindle taper | BT50 |

Spindle motor power | 2×22kW |

Maximum spindle torquen≤750r/min | 280Nm |

Distance from lower end face of main shaft to worktable | 280—780 mm (Adjust according to workpiece thickness) |

Gantry longitudinal movement (x-axis) | Maximum stroke | 4000 mm |

X-axis moving speed | 0—8m/min |

X-axis servo motor power | 2×2.7kW |

Lateral movement of power head (Y-axis) | Maximum distance between two power heads | 4000mm |

Y-axis moving speed | 0—8m/min |

Y-axis servo motor power | 2×2.7kW |

Feed motion of power head (Z axis) | Z-axis travel | 500 mm |

Z-axis feed speed | 0—4m/min |

Z-axis servo motor power | 2×3.3kW |

positioning accuracy | X-axis、Y-axis | 0.08/ whole course |

Repeat positioning accuracy | X-axis、Y-axis | 0.04/ whole course |

Hydraulic system | Hydraulic pump pressure / flow | 15MPa /25L/min |

Hydraulic pump motor power | 3.0 kW |

Pneumatic system | Air supply pressure | 0.5 MPa |

Chip removal and cooling | Chip conveyor type | Flat chain |

Number of chip conveyor | 2 |

Chip removal speed | 1m/min |

Chip conveyor motor power | 2×0.75kW |

Cooling mode | Internal cooling + external cooling |

Maximum pressure | 2MPa |

Maximum flow | 2×50L/min |

Electrical system | CNC | Siemens 828D |

CNC Number | 6 |

Total motor power | About75kW |

Overall dimensions of machine tool | Length× Wide × High | About 9m×9m×3m |

Total weight of machine tool |

| About 40t |

NO. | Name | Code | QTY |

1 | Photoelectric edge finder |

| 1 |

2 | inner hexagon spanner |

| 1 Set |

3 | Knife handle and pull nail | Φ40-BT50 | 2 |

4 | Knife handle and pull nail | Φ20-BT50 | 1 |

5 | Paint (for touch up) | -- | 2 Kegs |

NO. | Name | Brand | Country |

1 | linear guide rail | HIWIN/PMI | Taiwan, China |

2 | CNC | Siemens | Germany |

3 | Servo motor and driver | Siemens | Germany |

4 | Precision spindle | KENTURN /SPINTECH | Taiwan, China |

5 | Hydraulic valve | YUKEN / Justmark | Japan |

6 | Oil pump | Justmark | Taiwan, China |

7 | Automatic lubrication system | BIJUR / HERG | USA or Japan |

8 | Buttons, indicator lights and other main electrical components | SCHBEIDER/ABB | France /Germany |