Overview

Introduction to PLM6060/2 Gantry Movable CNC Drilling Machine

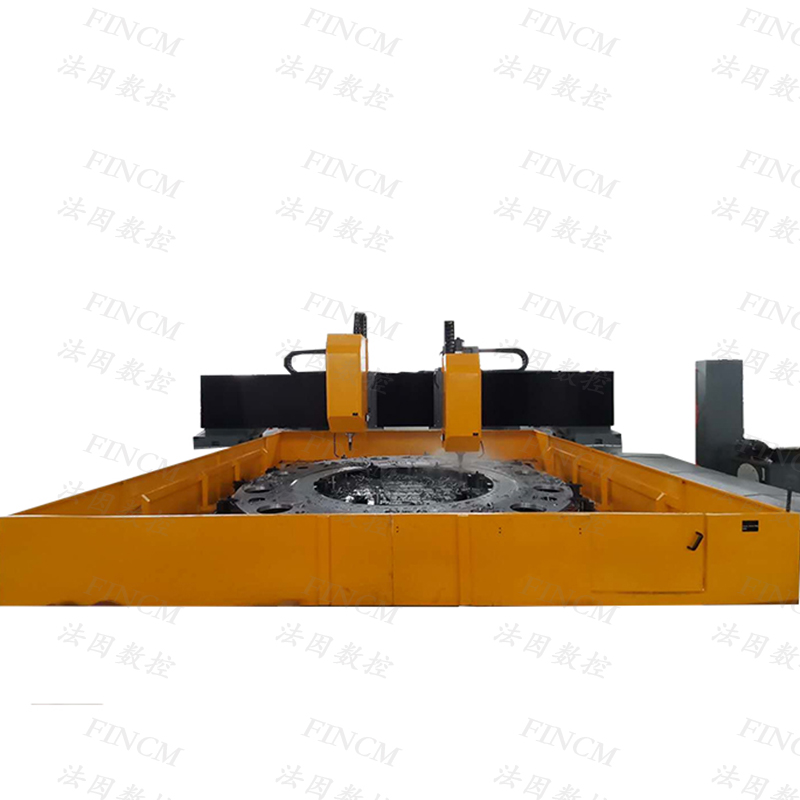

The gantry movable CNC plate drilling machine PLM6060/2 is a high-performance industrial equipment developed by FINCM, designed for precision machining of large-scale plate components. As a core product in CNC drilling technology, it integrates drilling, milling, grooving, chamfering, and light milling functions, providing an all-in-one solution for complex processing needs. This machine stands out for its stable structure, high positioning accuracy, and strong load-bearing capacity, making it an indispensable tool for heavy-duty plate processing.

Item | Name | Value |

Maximum Plate Size | L x W | 6000×6000 mm |

Maximum Thickness | 250 mm |

Work Table | T Slot Width | 28 mm(standard) |

Loading Weight | 3000KG/㎡ |

Drilling Spindle | Maximum Drilling Diameter | Φ60 mm |

Drilling spindle’s Rod Length vs. Hole diameter | ≤10 |

RPM | 30~3000 r/min |

Spindle Tape | BT50 |

Spindle motor power | 2*22kW |

Maximum Torque n≤750r/min | 280Nm |

Distance from Spindle bottom surface to the worktable | 280~780 mm (adjustable as per material thickness) |

Gantry Longitudinal Movement (X Axis) | Max. Travel | 6000 mm |

Movement speed along X axis | 0~8m/min |

Servo motor power of X axis | 2×2.7kW |

Spindle Transversal Movement (Y Axis) | Max. Travel | 6000mm |

Movement speed along Y axis | 0~8m/min |

Servo motor power of X axis | 2*2.14kW |

Spindle Feeding Movement (Z Axis) | Max. Travel | 500 mm |

Feeding speed of Z axis | 0~4m/min |

Servo motor power of Z axis | 2*3.3kW |

Positioning accuracy | X axis、Y axis | 0.12mm/full travel |

Repeatable positioning accuracy | X axis、Y axis | 0.06mm/full travel |

Hydraulic system | Hydraulic pump pressure/Flow rate | 15MPa /25L/min |

Hydraulic pump motor power | 3.0 kW |

Pneumatic system | Compressed air pressure | 0.5 MPa |

Scrap removal and Cooling system | Scrap removal tpe | Plate chain |

Scrap removal Nos. | 2 |

Scrap removal speed | 1m/min |

Motor Power | 2×0.75kW |

Cooling way | Inner cooling + Outside cooling |

Max. Pressure | 2MPa |

Max. Flow rate | 2*50L/min |

Electronic system | CNC control system | Siemens 828D |

CNC Axis Nos. | 6 |

Total power | About 75kW |

Overall Dimension | L×W×H | About 11m×11m×3m |

Machine weight |

| About 55000 KG |

Work Environment:

No. | Name | Size | Qty. |

1 | Optical edge finder |

| 1 piece |

2 | Inner hexagon wrench |

| 1 set |

3 | Tool holder and pull stud | Φ40-BT50 | 2 pcs |

4 | Tool holder and pull stud | Φ20-BT50 | 1 piece |

5 | Spare paints | -- | 2 kegs |

No. | Name | Brand | Country |

1 | Roller linear guide rail | Hiwin/HTPM | China Taiwan |

2 | CNC control system | Siemens | Germany |

3 | Servo motor and Servo driver | Siemens | Germany |

4 | Precise spindle | Kenturn/Spintech | China Taiwan |

5 | Hydraulic valve | Yuken/Justmark | Japan |

6 | Oil pump | Justmark | China Taiwan |

7 | Automatic lubricating system | BIJUR / Herg | USA/Japan |

8 | Button, Indicator, low voltage electronic components | ABB/Schneider | Germany/France |

Core Application & Industry Value

Targeting industries requiring high-precision plate machining, the PLM6060/2 delivers exceptional value by reducing processing cycles, improving product consistency, and minimizing manual intervention. It is widely recognized for solving pain points such as low efficiency and poor accuracy in traditional plate processing, becoming a cornerstone of modern manufacturing lines.

Key Features & Benefits

High-Precision Positioning System

Equipped with advanced servo control technology, the X/Y axis positioning accuracy reaches 0.12mm/full travel, and repeatable positioning accuracy is 0.06mm/full travel. This high-precision CNC drilling capability ensures consistent hole positions across large plates, eliminating rework caused by misalignment.

Multi-Process Integration Capability

Beyond drilling, the machine supports milling, grooving, and chamfering, realizing multi-process CNC machining in a single setup. This integration reduces workpiece transfer time, improves production efficiency by 30% compared to single-function equipment, and maintains processing precision.

High-Power Spindle Performance

The dual 22kW spindle motors (BT50 spindle taper) enable a maximum drilling diameter of Φ60mm, with a speed range of 30~3000 r/min. The powerful torque (280Nm at ≤750r/min) ensures smooth drilling of thick plates up to 250mm, suitable for high-strength materials.

Heavy-Duty & Stable Worktable

The worktable features a 28mm standard T-slot width and a loading capacity of 3000KG/㎡, supporting large plates up to 6000×6000mm. Its robust structure minimizes vibration during high-speed machining, safeguarding plate drilling precision.

Efficient Scrap Removal & Dual Cooling System

The plate chain scrap removal system (2 units, 1m/min speed) efficiently clears debris, while the inner+outer cooling design (2MPa pressure, 2×50L/min flow) extends tool life and ensures surface finish of workpieces.

Core Components & Quality Assurance

Premium Branded Components

The machine adopts world-class components: Hiwin/HTPM roller linear guide rails (China Taiwan) for smooth movement, Siemens servo motors & drivers (Germany) for precise control, Kenturn/Spintech precise spindles (China Taiwan) for stable performance, and Yuken/Justmark hydraulic valves (Japan) for reliable hydraulic operation.

Strict Quality Control Process

Every PLM6060/2 undergoes 72-hour continuous operation testing and precision calibration before delivery. Compliant with international manufacturing standards, it ensures long-term stable operation in harsh industrial environments.

Application Scenarios

Power Equipment Manufacturing

Ideal for drilling tube sheet and flange components in boilers, heat exchangers, and power generators, where high-precision hole patterns are critical.

Construction Machinery Components

Processes thick plates for excavator arms, crane frames, and engineering machine bases, meeting the demand for heavy-duty and high-strength parts.

Pressure Vessel & Heat Exchanger Production

Machines large-scale pressure vessel shells and heat exchanger plates, ensuring leak-proof performance through precise hole positioning.

Flange & Tube Sheet Processing

Specialized in flange drilling and tube sheet machining for petrochemical, pharmaceutical, and chemical industries, supporting custom hole layouts.

Action Call & After-Sales Service

Inquiry & Customization Support

Interested in optimizing your plate processing workflow? Contact us for a personalized quote or technical consultation. Our team will tailor solutions based on your specific workpiece size and processing requirements.

Comprehensive After-Sales Guarantee

We provide a 1-year warranty on core components, 24/7 technical support, and on-site installation & training. Spare parts are readily available to minimize downtime, ensuring your production line runs efficiently.