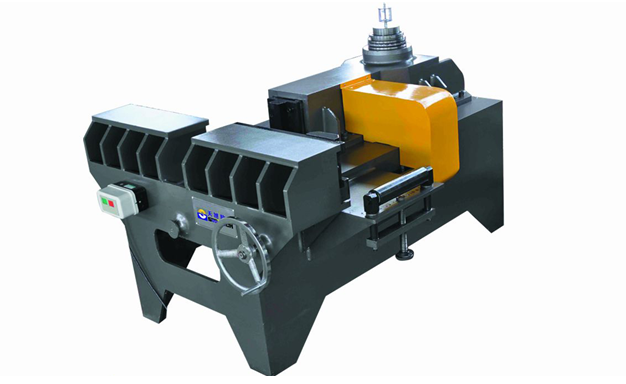

Product Overview

The DJ700D CNC Band Sawing Machine is a breakthrough for heavy H-beam fabrication, engineered to handle H-beams up to 700×300mm in cross-section—solving productivity challenges for large-scale construction, bridge, and industrial infrastructure projects. Its core advantages include CNC-controlled consistency (eliminating manual variability), 20% reduced material waste via nesting software, 60% higher productivity than manual saws, and compatibility with high-tensile steel (up to 690MPa).

Product Features

High-Capacity Cutting Performance

A reinforced saw frame and 18.5kW main motor deliver consistent cutting force for H-beams, I-beams, and square tubing (max 700mm dimension). The bi-metal band saw blade operates at 20–120m/min (automatic speed adjustment), ensuring clean, square cuts without material deformation.

Precision Positioning & Automated Handling

• Positioning: Servo-driven feeding (±0.5mm accuracy over 12m) + laser measurement system to compensate for material deflection; real-time encoder feedback for cut-to-length precision.

• Material Handling: 20-station powered roller conveyor, 50–300kN adjustable hydraulic clamping, and automatic discharge—enabling unattended 8-hour shifts.

Intelligent Cutting Management

Proprietary nesting software optimizes cut sequences to minimize waste. The CNC system stores 500 programs, monitors blade wear in real-time, and adjusts parameters to extend blade life to ~150 hours (standard conditions).

Applications

Heavy Structural Fabrication

The DJ700D is primarily used in manufacturing facilities producing H-beams for high-rise building frameworks, industrial plant structures, and large-span warehouses. Its ability to cut large sections with precision ensures proper fit-up during welding and assembly processes.

Bridge and Infrastructure Construction

In civil engineering projects, the machine processes heavy H-beams for bridge girders, overpass supports, and transportation hubs. The consistent cut quality is critical for these applications where structural integrity directly impacts public safety.

Offshore and Energy Structures

For offshore platforms, wind turbine support structures, and power plant frameworks, the DJ700D cuts thick-walled H-beams that form the backbone of these critical energy infrastructure projects.

Heavy Machinery Manufacturing

Manufacturers of construction equipment, cranes, and material handling systems utilize the machine to produce precision-cut H-beam components for machinery frames and load-bearing structures.

FAQ

What type of band saw blade is recommended for the DJ700D?

We recommend bi-metal band saw blades with 8–12 teeth per inch (TPI) for most H-beam applications. For high-tensile steel cutting, carbide-tipped blades are available as an option, which can extend blade life by up to 300% compared to standard bi-metal blades.

What is the machine’s production capacity per shift?

In an 8-hour shift processing 6-meter H-beams of 500×200mm cross-section, the DJ700D can produce approximately 250–300 cut pieces depending on cut length. This represents a 60% increase in productivity compared to manual band saws.

How long does blade replacement take?

The quick-change blade system allows operators to replace and tension the blade in under 10 minutes. The machine includes blade tension monitoring that alerts operators to improper tension settings before cutting begins.

Can the machine cut non-ferrous materials?

While optimized for structural steel, the DJ700D can cut aluminum and copper alloys with appropriate blade selection. The CNC system includes specific parameter profiles for non-ferrous materials to prevent blade clogging and ensure clean cuts.

What maintenance is required?

Daily maintenance includes checking coolant levels and cleaning the chip conveyor. Weekly tasks involve inspecting blade tension, lubricating guide rollers, and verifying clamping pressure. The control system provides predictive maintenance alerts, with major overhauls recommended every 6,000 operating hours.

Saw out H-beam steel dimensions (without turning corners) | 200 ×75 mm~700 ×500 mm |

Maximum cutting capacity at 45 ° | 400 × 500mm |

Maximum cutting capacity at 60 ° | 200 × 500mm |

hacksaw blade | T:W:54mm |

Motor power

| Main motor | 7.5 kW |

hydraulic pump | 5.5kW |

Saw blade linear speed | 20~/min |

Sawing feed rate | program control |

Slant angle | -60°~0°~60° |

Workbench height | About |

Main clamping hydraulic motor | 100ml/r |

Front clamping hydraulic motor | 100ml/r |

External dimensions of the host (length * width * height) | About 3100x4000x2800 mm |

NO. | Name | Brand | Country |

1 | Linear guide rail | HIWIN | Taiwan (China) |

2 | Hydraulic motor | Justmark | Taiwan (China) |

3 | Magnetic grating ruler | SIKO | Germany |

4 | hydraulic pump | Carnival | Taiwan (China) |

5 | Electromagnetic hydraulic valve | ATOS/ YUKEN | Italy / Japan |

6 | Proportional valve | ATOS | Italy |

7 | Saw blade | Renault/WIKUS | USA/Germany |

8 | Inverter | INVT / Inovance | China |

9 | Programmable controller | Mitsubishi | Japan |

10 | touch screen | Cermate | Taiwan (China) |

Note: The above is our fixed supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter

NO. | Name | Quality | Remark |

1 | Special Band Saw Blade for H-Beams | 2 | Including that on machine |

2 | Ring type Nylon Wire Brush | 6 | Including that on machine |

3 | Spare paint | 2 | 1 key of main color 1 key of warning color |

4 | Multi functional metal cutting fluid | 1 | Solid power |