Overview

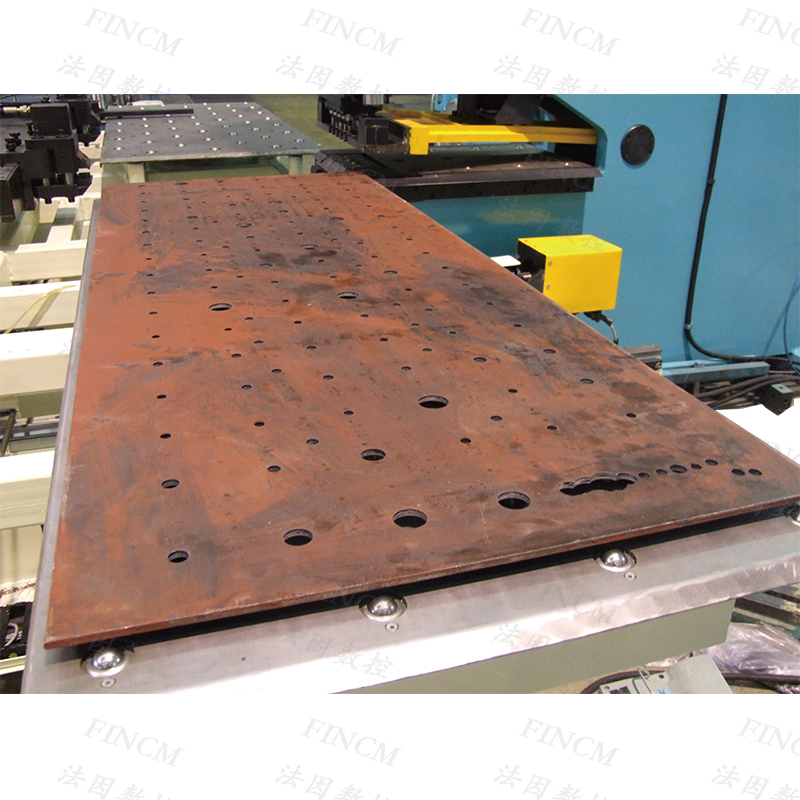

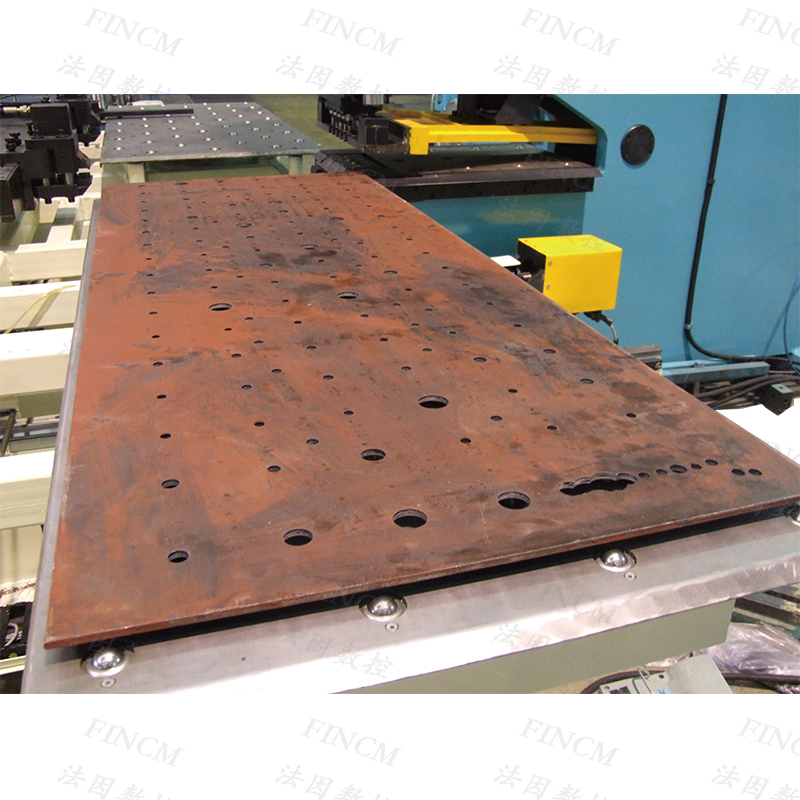

The CNC Hydraulic High-speed Plate Punching Machine PP1213A is a professional precision equipment tailored for the truck industry, specifically designed for punching small and medium-sized plates used in truck chassis and automobile trabeculae. With advanced CNC control and hydraulic drive technology, this machine achieves high-precision hole positioning through one-time clamping, eliminating repeated setup errors and ensuring consistent workpiece quality. It stands out for its high-speed punching capability and fully automated operation, making it an ideal choice for mass production of truck-related plate components. The PP1213A supports processing plates up to 800mm×3500mm in one positioning and extends to 800mm×7000mm via auxiliary clamp transfer, meeting the diverse size requirements of truck chassis manufacturing.

Key Features & Benefits

High-Precision Positioning & Stable Hole Accuracy

Equipped with a high-performance CNC system and servo drive, the PP1213A delivers exceptional X/Y axis positioning accuracy: ±0.2mm for hole spacing ≤400mm, ±0.30mm for 400-2000mm, and ±0.50mm for 2000-3500mm (±1mm for secondary positioning up to 7000mm). This precision ensures tight fitment of truck chassis components, reducing assembly gaps and enhancing overall structural stability.

High-Speed Punching & Efficient Production

Boasting a punching speed of over 42 holes per minute, the machine significantly outperforms traditional punching equipment, cutting production cycles for truck plate parts by 30% or more. The 1200KN punching force enables smooth processing of plates 4-12mm thick, handling high-strength steel commonly used in truck chassis without deformation.

Flexible Plate Handling & Wide Adaptability

With 3 clamps and dual-positioning capability, the PP1213A accommodates plates from 800×3500mm (one-time clamping) to 800×7000mm (secondary transfer). It supports 13 punching stations and a full set of dies (φ9-φ65mm), covering most hole sizes required for truck chassis trabeculae, crossbeams, and brackets.

Automated Operation & Labor Savings

The fully CNC-controlled workflow minimizes manual intervention—from plate clamping to punching completion, the machine operates independently. This reduces labor costs and human errors, ensuring consistent quality even during long-hour mass production runs.

Technical Specifications

Punching & Plate Parameters

Punching Force: 1200KN

Maximum Plate Size: 800×3500mm (one-time positioning); 800×7000mm (secondary positioning)

Plate Thickness Range: 4-12mm

Punching Stations: 13

Maximum Punch Diameter: φ65mm

Punch Sizes: φ9、φ11、φ13、φ15、φ17、φ21、φ22、φ30、φ34、φ36、φ45、φ50、φ65mm (with 8mm/6mm die set)

Punching Speed: >42 holes/minute

Power & Pressure Specifications

Hydraulic Pump Motor Power: 22kW

X/Y-axis Servo Motor Power: 5kW each

Total Capacity: 55kVA

System High Pressure: 24MPa; Low Pressure: 6MPa

Air Pressure Requirement: 0.5MPa

Precision & Tolerance

Warpage Tolerance: <25mm

Minimum Hole Edge Distance: Refer to tool layout diagram

Core Components & Quality Assurance

Premium Imported & Domestic Components

The PP1213A adopts world-class core parts to ensure reliability:

CNC System: Siemens 808D (Germany) – Ensures fast response and precise control

Servo Motor & Driver: Siemens/Panasonic (Germany/Japan) – Delivers stable power output

Linear Motion Guide Rail: HIWIN/PMI (Taiwan, China) – Reduces friction for smooth movement

Ball Screw: I+F/NEEF (Germany) – Enhances positioning accuracy

Hydraulic Valve: ATOS (Italy) – Maintains stable pressure during high-load operation

Low-Voltage Electricals: Schneider (France) – Ensures safe and durable electrical performance

Strict Quality Control & Replacement Guarantee

All components are sourced from fixed, certified suppliers. In case of supply shortages, equivalent-quality parts from reputable brands are used. The machine undergoes 72-hour continuous operation testing before delivery, ensuring compliance with international industrial standards.

Application Scenarios

Truck Industry Core Applications

Truck chassis trabeculae, crossbeams, and frame brackets punching

Medium-duty and heavy-duty truck plate component mass production

Customized hole punching for truck body accessories (e.g., lashing points, mounting holes)

Extended Automotive & Industrial Uses

Automobile trabeculae and sheet metal part processing

Construction machinery (e.g., forklift, excavator) plate punching

High-volume production of standard or customized metal plates requiring precise holes

Action Call & After-Sales Service

Take Immediate Action

Ready to boost your truck chassis production efficiency? Inquire now for a customized quote or Add to Basket to secure your PP1213A. We offer flexible payment terms and fast global shipping to meet your production deadlines.

Comprehensive After-Sales Support

1-year warranty on the entire machine (2 years for core components like CNC system and servo motors)

24/7 technical support via phone, email, and video call

On-site installation, commissioning, and operator training

Permanent supply of spare parts at factory-direct prices

Regular maintenance reminders and professional maintenance services

Punching Force | KN | 1200 |

Maximum plate size (Width x Length) | mm | 800×3500 (one time’s positioning) 800×7000(Secondary positioning) |

Plate thickness range | mm | 4~12 |

Punching Station | Punching position number |

| 13 |

Maximum punch diameter | mm | φ65 |

Punch size (mm) | φ9、φ11、φ13、φ15、φ17、φ21、φ22、φ30、φ34、φ36、φ45、φ50、φ65(A set of die with plate thickness of 8mm or 6mm) |

Number of punches | Per minute | 〉42 |

Warpage | mm | <25 |

Minimum distance from hole centerline to the boundary edge | mm | See punching tool layout picture |

Number of clamps |

| 3 |

System pressure | high pressure | MPa | 24 |

low pressure | MPa | 6 |

Air pressure | MPa | 0.5 |

Motor power of hydraulic pump | kW | 22 |

X-axis servo motor power | kW | 5 |

Y-axis servo motor power | kW | 5 |

Total capacity | kVA | 55 |

Work Condition | Accuracy of X, Y axis |

When the hole spacing is less than or equal to 400mm | ±0.2mm |

When the hole spacing is greater than 400mm and less than 2000mm | ±0.30mm |

When the hole spacing is more than 2000mm and less than 3500mm | ±0.50mm |

When the hole spacing is more than 3500mm and less than 7000mm | ±1mm (Secondary positioning) |

NO | Name | Brand | Country |

1 | CNC | Siemens 808D | Germany |

2 | Servo motor and servo driver | Siemens / Panasonic | Germany/ Japan |

3 | Linear motion guide rail | HIWIN/PMI | Taiwan, Chian |

4 | Ball screw | I+F/NEEF | Germany |

5 | Cylinder | SMC/FESTO | Japan /Germany |

6 | Solid state relay | Weidmuller | Germany |

7 | Towline | Igus/CPS | Germany/ South Korea |

8 | Double vane pump | Denison/Albert | USA |

9 | Hydraulic Valve | ATOS | Italy |

10 | Oil cooler | Tongfei/Laber | China |

11 | Oil lubrication device | Herg | Japan |

12 | Low voltage electrical components | Schneider | France |

Note: The above is our fixed supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.

1).Power supply: 3 phase 4 lines 380±10%V 50±1HZ

2).Compressed air pressure: ≥0.5MPa

3).Temperature: 0

4).Humidity: ≤75%