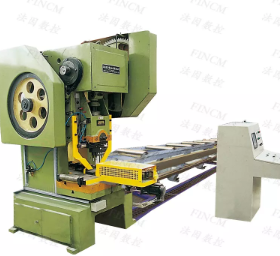

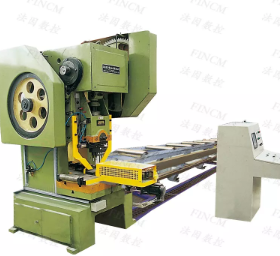

Product Overview

The FJC23 Series Mechanical Punching Press is a workhorse for high-volume steel punching, combining flywheel-driven speed with modern control systems—ideal for fabricators producing structural components (plates, angles, channels) for construction, machinery, and infrastructure. Key benefits include 30% faster cycle times than hydraulic presses, 2000kN nominal punching force (for φ32mm holes in 25mm mild steel), ±0.1mm positioning accuracy, and a durable cast iron frame (15,000+ operating hours).

Product Features

High-Force Punching Capability

The press delivers a nominal punching force of 2000 kN, enabling it to punch holes up to φ32mm in steel plates up to 25mm thick (mild steel). The mechanical drive system generates consistent force throughout the punching stroke, ensuring clean, burr-free holes with minimal material deformation. A replaceable punch and die system accommodates various hole sizes, with standard tooling sets covering diameters from φ8mm to φ32mm.

Rapid Production Cycles

Equipped with a high-speed clutch-brake system, the press achieves a maximum punching rate of 60 strokes per minute for small holes in thin material. The flywheel design maintains consistent speed even during continuous operation, reducing cycle time by approximately 30% compared to equivalent hydraulic presses. This high throughput makes it ideal for mass production of structural components requiring multiple holes.

Versatile Workpiece Handling

The machine features a large worktable with 2000mm × 800mm working area, accommodating steel plates up to 2500mm in length with optional support rollers. A programmable backgauge with ±0.1mm positioning accuracy allows for precise hole spacing, with memory storage for up to 100 different punching patterns. The backgauge travels up to 1500mm, supporting long workpieces without manual repositioning.

Durable Construction

Built for industrial longevity, the press features a one-piece cast iron frame with reinforced ribbing to withstand high punching forces without deflection. Key components including the crankshaft and connecting rods are manufactured from forged alloy steel, providing a service life of over 15,000 operating hours under standard conditions. The enclosed drive system protects internal components from dust and debris, reducing maintenance requirements.

Applications

Structural Steel Fabrication

The primary application is punching connection holes in steel plates, angles, and channels used in building frameworks, industrial structures, and prefabricated construction components. Its high throughput makes it suitable for mass-producing bracket plates, gusset plates, and flange connections.

Machinery Manufacturing

In heavy machinery production, the press punches precision holes in machine frames, base plates, and structural components. The consistent hole quality ensures proper alignment of moving parts and fasteners during assembly.

Infrastructure Components

The machine produces punched steel components for bridge structures, highway guardrails, and transportation infrastructure. Its ability to process thick materials makes it ideal for heavy-duty infrastructure applications requiring high-strength connections.

Storage and Shelving Systems

Manufacturers of industrial shelving, racking, and storage systems utilize the press to produce uniformly punched uprights and cross-members, ensuring modular compatibility across system components.

FAQ

What is the maximum material thickness the press can handle?

For carbon steel (ASTM A36), the press can reliably punch 25mm thick material with a maximum hole diameter of φ20mm. For thicker materials up to 30mm, we recommend reducing the maximum hole diameter to φ16mm to maintain optimal performance and tool life.

How long do punch and die tools typically last?

Under standard operating conditions with proper lubrication, punch tools achieve approximately 100,000 punches in 12mm mild steel before requiring replacement. Dies typically last 300,000 punches under the same conditions. Tool life decreases with harder materials or increased thickness.

What safety features are included?

Safety features include a two-hand operation system that requires both hands to be on palm buttons before cycling, an interlocked safety guard around the working area, and an emergency stop button that immediately halts all operations. Optional light curtain systems are available for enhanced operator protection.

Can the machine be automated for unattended operation?

Yes, the press can be integrated with optional automatic feeding systems for coil or sheet material, enabling unattended production. The CNC control system supports interface with robotic loading/unloading systems for fully automated manufacturing cells.

What power supply is required?

The press operates on a three-phase power supply with 380V AC voltage, 50Hz frequency, and requires a dedicated 100A electrical supply. It also requires compressed air at 0.6–0.8MPa for the clutch and brake system.

Technical Parameters :

Item/model | Units | FJC23-16T |

Nominal pressure | KN | 160 |

Nominal pressure stroke | mm | 5 |

Slide stroke | mm | 55 |

Slide stroke times | times/min | 120 |

Max. die. Height | mm | 180 |

Die height adjustment | mm | 45 |

Distance between center of slide and frame | mm | 160 |

Table thickness | mm | 40 |

Distance between column | mm | 220 |

Work table size | mm | 300x450 |

Hole dimensions in bed | mm | Φ100 |

Bottom size of slide | mm | 150x170 |

Size of the handle hole | mm | Φ40x60 |

Motor power | kw | 1.5 |

Machine size | mm | 1050x800x1910 |

Max. angle of inclination | deg | 25° |

Total weight | kg | 1000 |

FJC23-25T

Item/model | Units | JC23-25T |

Nominal pressure | KN | 250 |

Nominal pressure stroke | mm | 6 |

Slide stroke | mm | 70 |

Slide stroke times | times/min | 60 |

Max. die. Height | mm | 200 |

Die height adjustment | mm | 45 |

Distance between center of slide and frame | mm | 200 |

Table thickness | mm | 50 |

Distance between column | mm | 250 |

Work table size | mm | 330x525 |

Hole dimensions in bed | mm | Φ130 |

Bottom size of slide | mm | 160x200 |

Size of the handle hole | mm | Φ40x60 |

Motor power | kw | 2.2 |

Machine size | mm | 1200x880x2075 |

Max. angle of inclination | deg | 25° |

Total weight | kg | 1800 |

FJC23-40T

Item/model | Units | JC23-40T |

Nominal pressure | KN | 400 |

Nominal pressure stroke | mm | 6 |

Slide stroke | mm | 80 |

Slide stroke times | times/min | 50 |

Max. die. Height | mm | 250 |

Die height adjustment | mm | 60 |

Distance between center of slide and frame | mm | 210 |

Table thickness | mm | 65 |

Distance between column | mm | 300 |

Work table size | mm | 410x630 |

Hole dimensions in bed | mm | Φ150 |

Bottom size of slide | mm | 190x210 |

Size of the handle hole | mm | Φ50x70 |

Motor power | kw | 4 |

Machine size | mm | 1500x1100x2250 |

Max. angle of inclination | deg | 25° |

Total weight | kg | 2960 |

FJC23-63T

Item/model | Units | JC23-63T |

Nominal pressure | KN | 630 |

Nominal pressure stroke | mm | 8.5 |

Slide stroke | mm | 120 |

Slide stroke times | times/min | 50 |

Max. die. Height | mm | 270 |

Die height adjustment | mm | 80 |

Distance between center of slide and frame | mm | 260 |

Work table size | mm | 480x710 |

Hole dimensions in bed | mm | Φ150 |

Work table thickness | mm | 90 |

Bottom size of slide | mm | 270x310 |

Size of the handle hole | mm | Φ50x70 |

Between columns | mm | 350 |

Motor power | kw | 5.5 |

Machine size | mm | 1850x1300x2680 |

Max. angle of inclination | deg | 25° |

Total weight | kg | 4000 |

FJC23-80T

Item/model | Units | JC23-80T |

Nominal pressure | KN | 800 |

Nominal pressure stroke | mm | 8.5 |

Slide stroke | mm | 120 |

Slide stroke times | times/min | 50 |

Max. die. Height | mm | 270 |

Die height adjustment | mm | 80 |

Distance between center of slide and frame | mm | 260 |

Table thickness | mm | 90 |

Distance between column | mm | 350 |

Work table size | mm | 480x800 |

Hole dimensions in bed | mm | Φ220 |

Bottom size of slide | mm | 270x310 |

Size of the handle hole | mm | Φ50x70 |

Motor power | kw | 7.5 |

Machine size | mm | 1850x1300x2680 |

Max. angle of inclination | deg | 20° |

Total weight | kg | 5000 |