Overview

The CNC Drilling Machine for Boiler Shell is a specialized marvel of engineering, meticulously crafted to meet the unique challenges of boiler shell manufacturing. This high-precision machine is the cornerstone of efficiency and accuracy in the production of boiler shells, which are critical components in power generation and industrial heating systems. With its advanced CNC technology and robust construction, the machine delivers unparalleled accuracy and repeatability, making it an essential tool for any boiler manufacturing facility that demands the highest standards of quality and performance.

Features

· CNC Precision

At the core of this machine's operation is its sophisticated CNC system, which allows for precise control over drilling operations. Operators can input detailed drilling patterns and specifications, and the machine will execute them with unwavering accuracy, ensuring that each hole is placed exactly where it needs to be.

· Heavy-Duty Construction

The machine's robust frame and components are built to withstand the rigors of heavy industrial use. It is designed to handle the stresses of drilling through thick boiler shell materials, ensuring that it can maintain its performance over long periods of continuous operation.

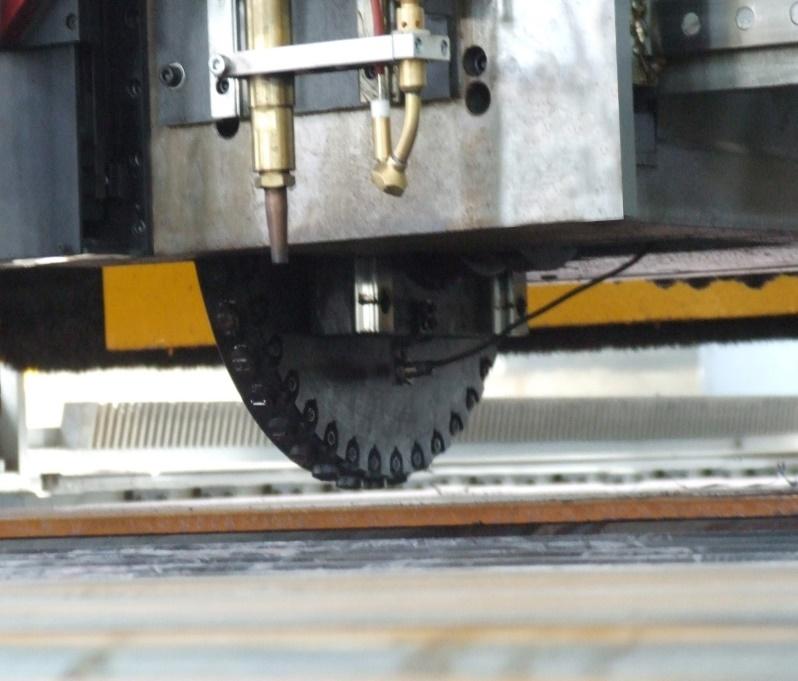

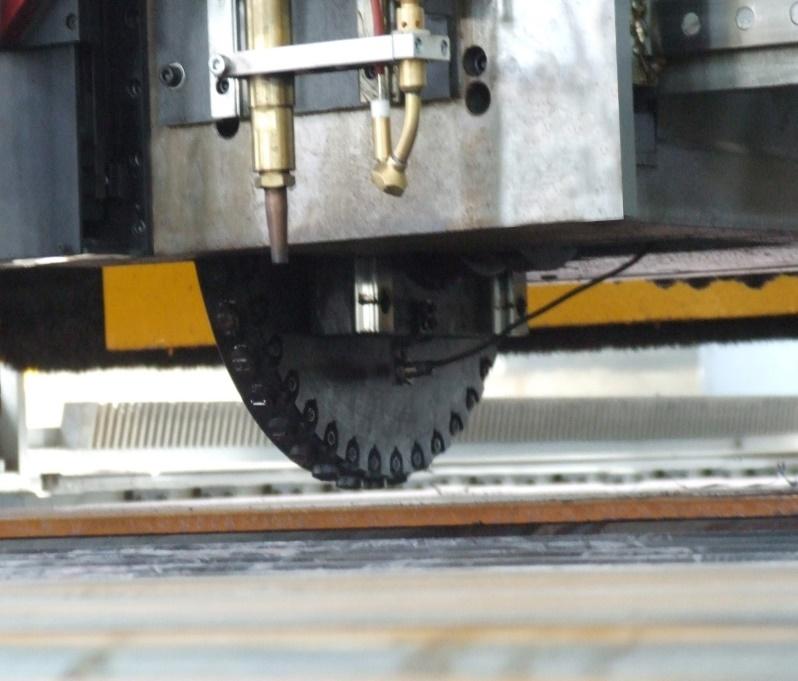

· High Torque Spindle

The high-torque spindle is a powerhouse, capable of maintaining consistent performance even when drilling through the toughest materials. This ensures a smooth and efficient drilling process, reducing the risk of wear and tear on both the machine and the material.

· Automatic Positioning

The CNC drilling machine includes an automatic positioning system that allows for rapid and accurate adjustments between drilling points. This feature significantly reduces setup time, allowing for a more streamlined production process.

· Durable Tooling

The machine is equipped with durable and long-lasting tooling that can withstand the demands of continuous use in a heavy industrial environment. This reduces the need for frequent tool changes and minimizes downtime.

· Safety and Stability

Safety is paramount in any manufacturing environment, and this machine is equipped with features such as emergency stop buttons and stable workholding to ensure that it can be operated with confidence. The machine's design also includes features that minimize vibrations and ensure stability during operation, which is crucial for maintaining precision.

Applications

· Power Generation

In the power generation industry, where reliability and safety are critical, this machine is used for drilling holes for tube attachments, manholes, and other critical components in power plant boilers. The precision of this machine ensures that each hole is drilled to the exact specifications, ensuring the safe and efficient operation of the boiler.

· Industrial Heating

For manufacturers of industrial heating systems, this machine is essential for the production of boilers used in factories, refineries, and other industrial heating applications. The ability to drill with high precision ensures that these boilers can operate at peak efficiency and safety.

· Shipbuilding

In the shipbuilding industry, where space and weight are at a premium, the machine is used to drill holes in marine boilers with pinpoint accuracy. This ensures that the boilers are not only efficient but also meet the strict safety standards required for marine applications.

· Custom Manufacturing

For companies that require specialized boiler shells with custom hole patterns and specifications, this CNC drilling machine is the perfect solution. It allows for the creation of custom designs that meet the unique needs of each customer, ensuring that their boilers are tailored to their specific requirements.

This CNC drilling machine is more than just a piece of equipment; it's a partner in the pursuit of manufacturing perfection, providing manufacturers with the ability to produce high-quality boiler shells with greater speed, accuracy, and reliability than ever before.

1) Technical specification of HD1814-3

Workpiece size | Barrel diameter range | Min. Φ780 ~ Max. Φ1800mm |

Barrel length range | 2~14m |

Maximum wall thickness | 50mm |

Maximum weight of workpiece | 15000 kG |

Maximum diameter of drilling holes | Φ65mm |

Hole spacing accuracy | Distance between adjacent holes:±1.0mm Farthest hole distance:±1.5mm |

Power head of drilling spindle | Type | Hydraulic slide, Fast forward work forward fast backward automatic conversion |

Quantity | 3 |

Spindle taper hole | 6 |

Spindle speed | 80-200r/min |

Spindle stroke | 500mm |

spindle feed speed (hydraulic stepless) | 10-200mm/min |

Spindle motor power | 3x7.5kW |

X-axis positioning accuracy | 0.2mm |

Working temperature of hydraulic oil | ≤60℃ |

Laser alignment device | Adjust hole group position according to weld position |

Workpiece rotation speed | 0~2.8r/min |

Moving speed of slide | 0~10m/min |

Power of tail seat drive motor | 2.2kW |

Servo motor power of slide drive | 3X2kW |

Cooling pump motor power | 450W |

Chip conveyor drive motor power | 750W |

Height between chuck center and ground | About 1570mm |

Machine tool overall dimension (L x W x H) | About 22x5x |

Working environment:

l Power supply: 3 phase 4 lines 380±10%V 50±1HZ

(or made to order)

l Compressed air pressure: ≥0.5MPa

l Temperature: 0

l Humidity: ≤75%

2) List of the Key Outsourced Components of HD1814-3

NO | Name | Brand | Country |

1 | linear guide rail | HIWIN/PMI | Taiwan, China |

2 | Precision reducer and rack and pinion pair | ATLANTA | Germany |

3 | Numerical control system | Siemens 808D | Germany |

4 | servo motor | Siemens | Germany |

5 | Slide drive servo motor and driver | Siemens | Germany |

6 | Frequency converter | Siemens | Germany |

7 | Hydraulic pump | justmark | Taiwan, China |

8 | Hydraulic valve | ATOS/Justmark | Italy / Taiwan, China |