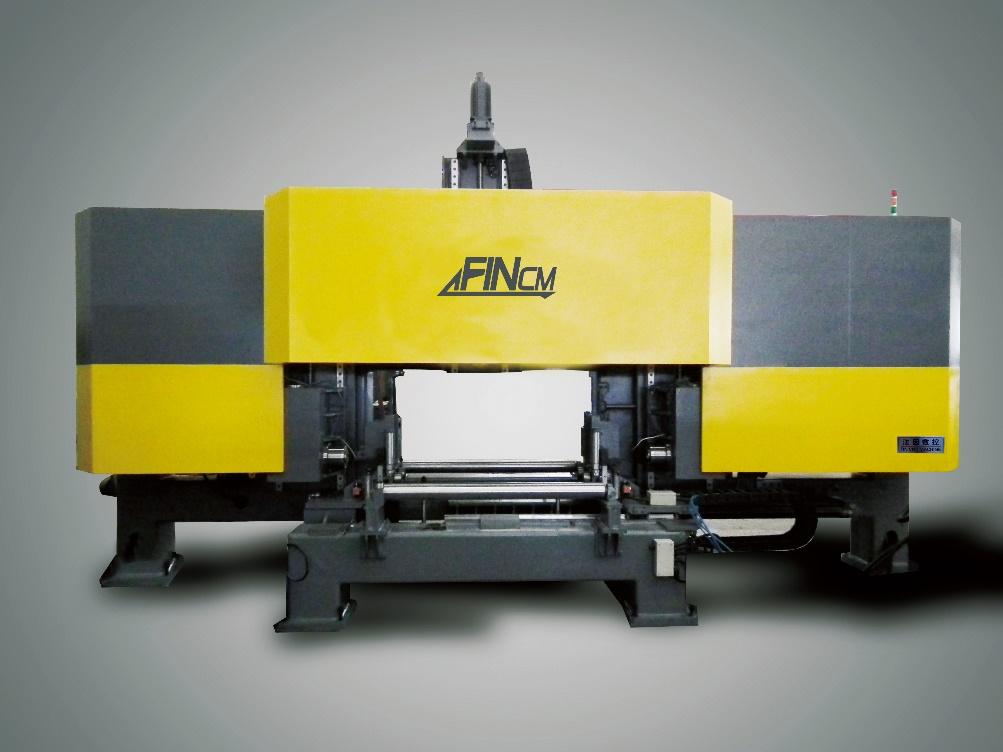

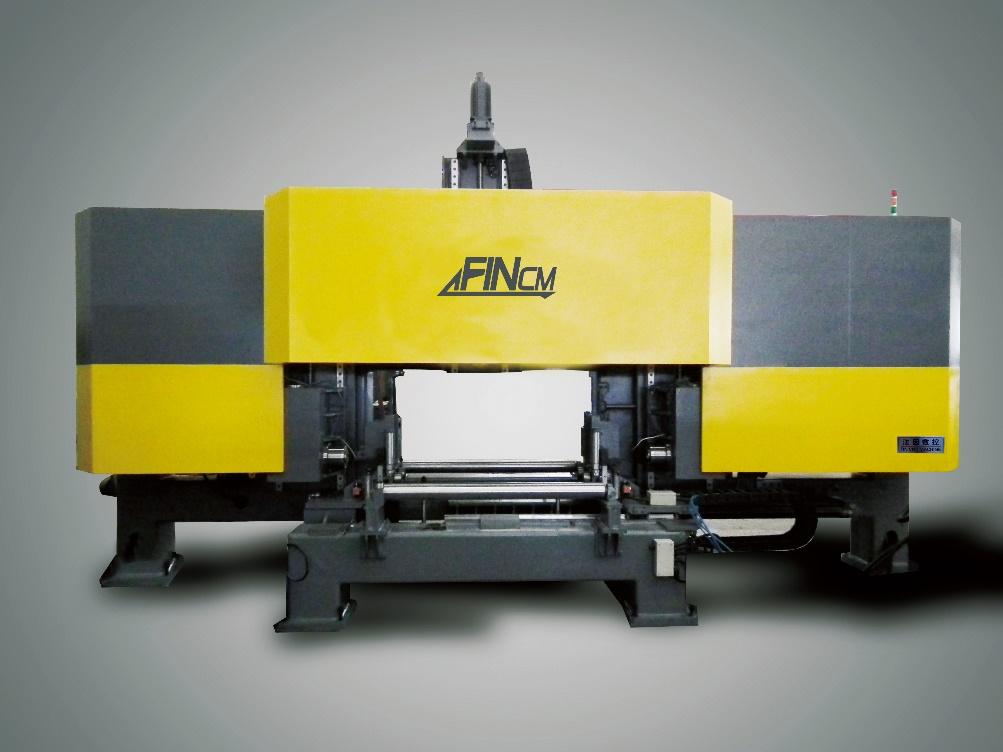

Product Overview

High-Efficiency Drilling for H-Beams and Steel Profiles

This CNC high-speed drilling machine is a specialized solution for processing large-size steel beams such as H-beams and box girders. It offers three independently controlled spindles for simultaneous web and flange drilling, drastically improving throughput in structural steel fabrication. With intelligent servo positioning, automatic data recognition, and robust CNC control, this machine is ideal for heavy-duty projects requiring high-volume, high-precision hole processing.

The system is capable of reading DSTV/NC1 files directly and converting CAD hole data into optimized drilling instructions. Its reinforced base, high-torque spindles, and programmable logic controller ensure smooth performance in long-term, multi-shift workshop environments.

Key Features

Triple-Axis Drilling Without Repositioning

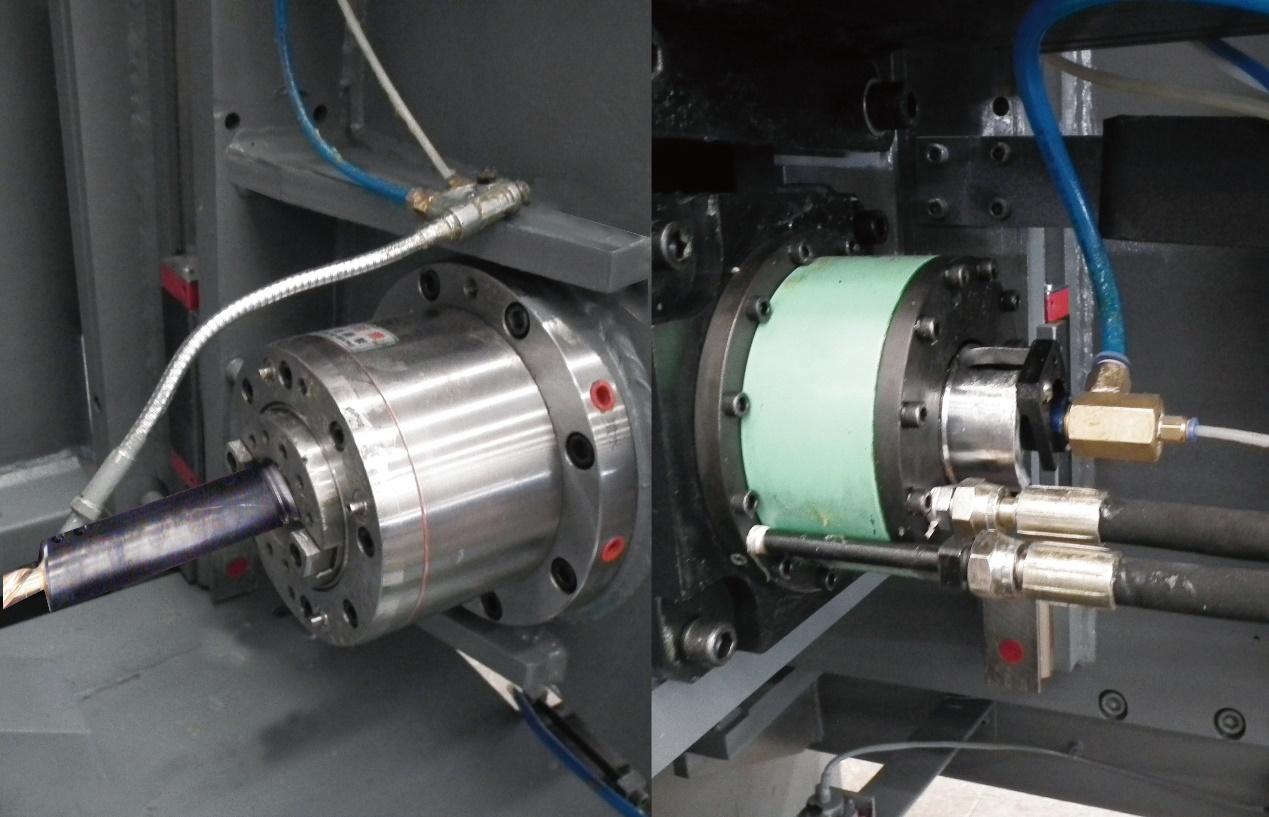

Three vertical and horizontal spindles enable simultaneous drilling on the top, left, and right surfaces of the beam. This configuration eliminates the need to rotate or flip the workpiece, significantly reducing idle time and alignment errors.

Fast and Accurate Servo Positioning

A servo-driven trolley system positions the beam based on CNC-calculated coordinates with encoder feedback, delivering precision up to ±0.1 mm even for long beams or dense hole groups.

CNC System with Automated Workflow

The user-friendly Siemens control interface supports DSTV/NC1 file import, automatic hole grouping, spindle speed adjustment, and tool life monitoring. The system supports offline programming and remote diagnostics to simplify operator tasks and ensure production continuity.

Low-Maintenance Operation

The drilling unit is equipped with internal coolant supply, centralized lubrication, and automatic chip removal. These systems ensure smooth operation in demanding environments while reducing downtime and maintenance cost.

Technical Parameters

| Item | Specification |

| Workpiece Type | H-Beam, Channel Steel, Box Girders |

| Workpiece Height | 150–1000 mm |

| Flange Width | 75–400 mm |

| Max. Workpiece Length | 12,000 mm (customizable) |

| Drilling Diameter Range | 12–33.5 mm |

| Max. Hole Depth | ≤40 mm |

| Drilling Spindles | 3 (Top, Left, Right) |

| Spindle Power | 5.5 kW × 3 |

| Spindle Speed | 180–560 rpm (adjustable) |

| Beam Feeding Speed | 0–8 m/min |

| Positioning Accuracy | ±0.1 mm |

| Control System | Siemens 828D or equivalent |

| Cooling & Chip Removal | Internal coolant + chain-type chip conveyor |

Functional Configuration

| Module | Description |

| CNC Controller | Siemens interface with multilingual support and remote access |

| Beam Feeding System | Servo-driven trolley with clamping arms and encoder feedback |

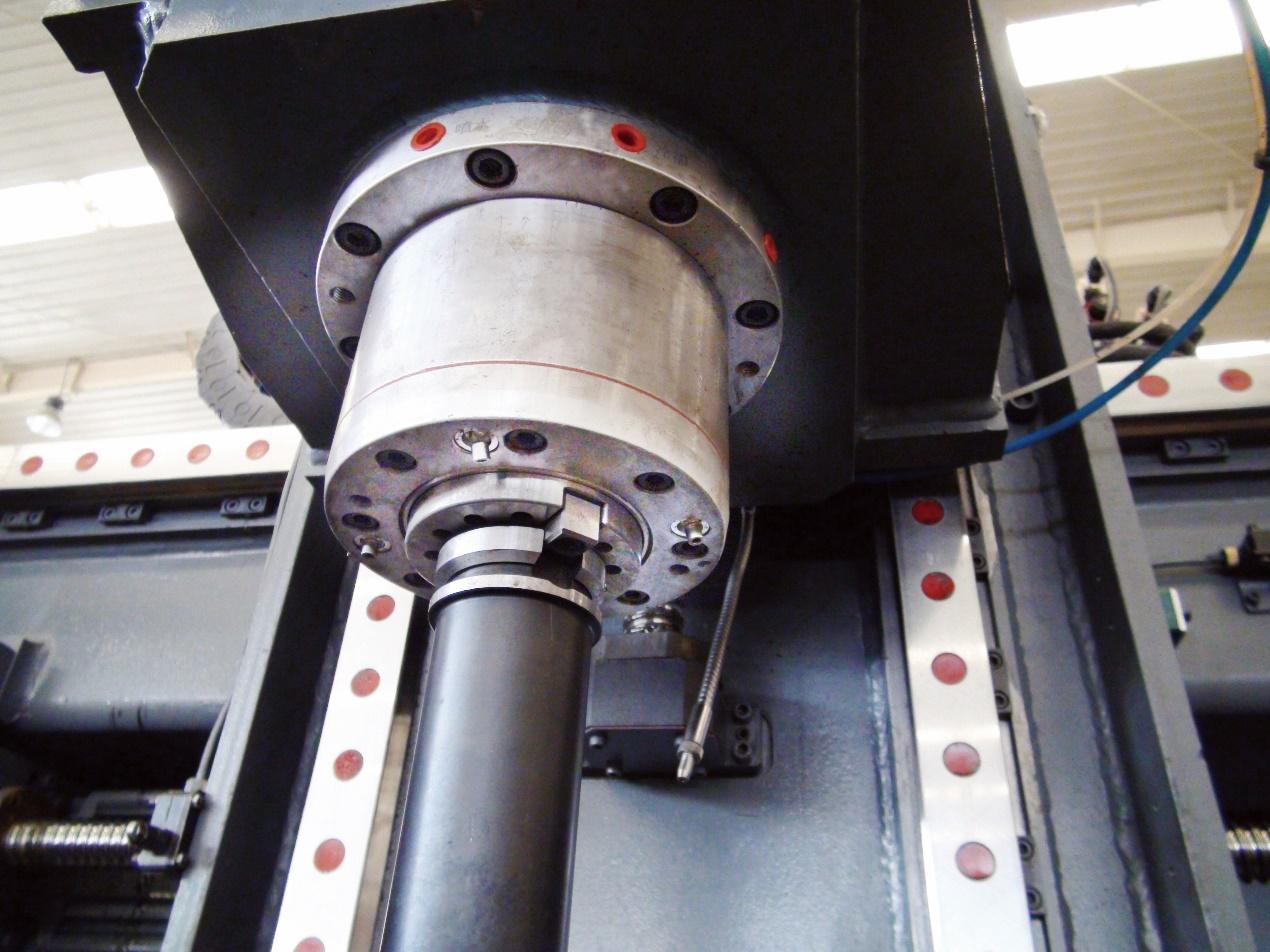

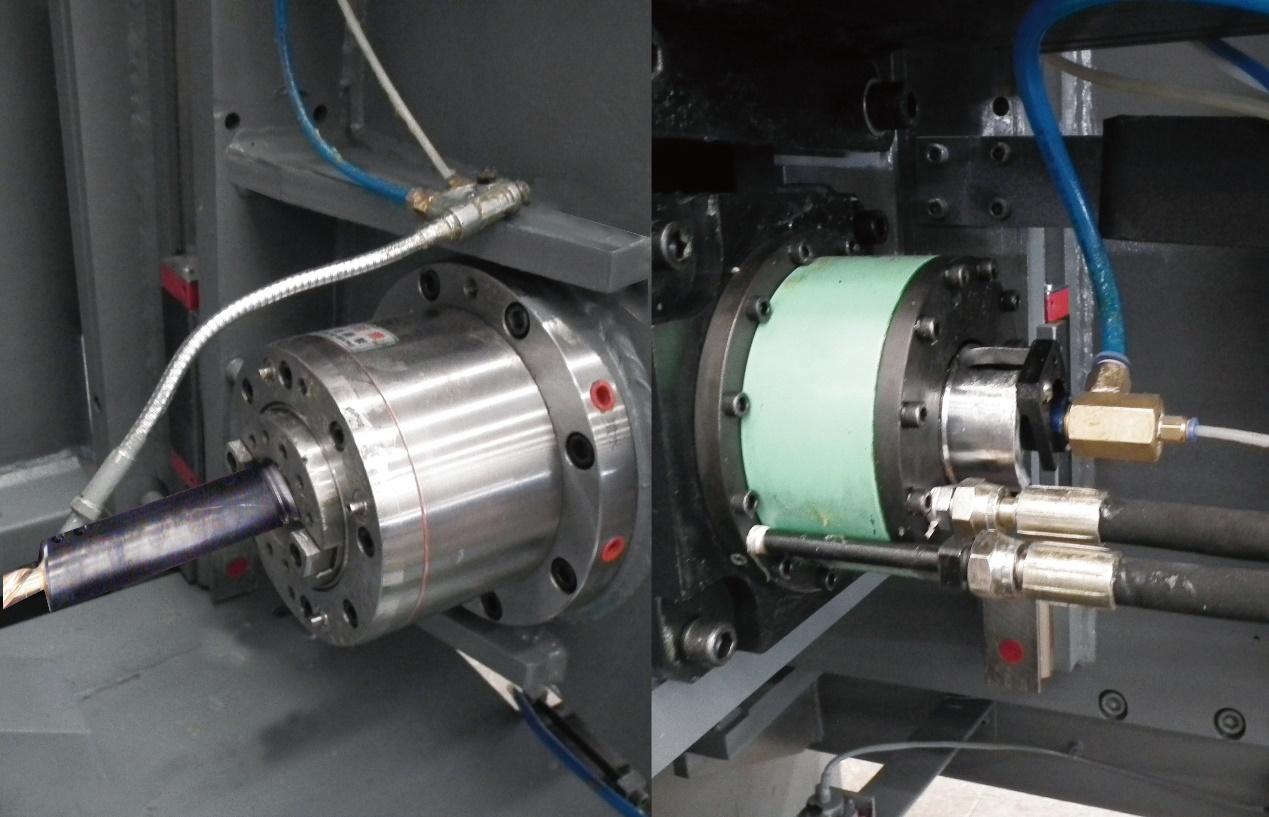

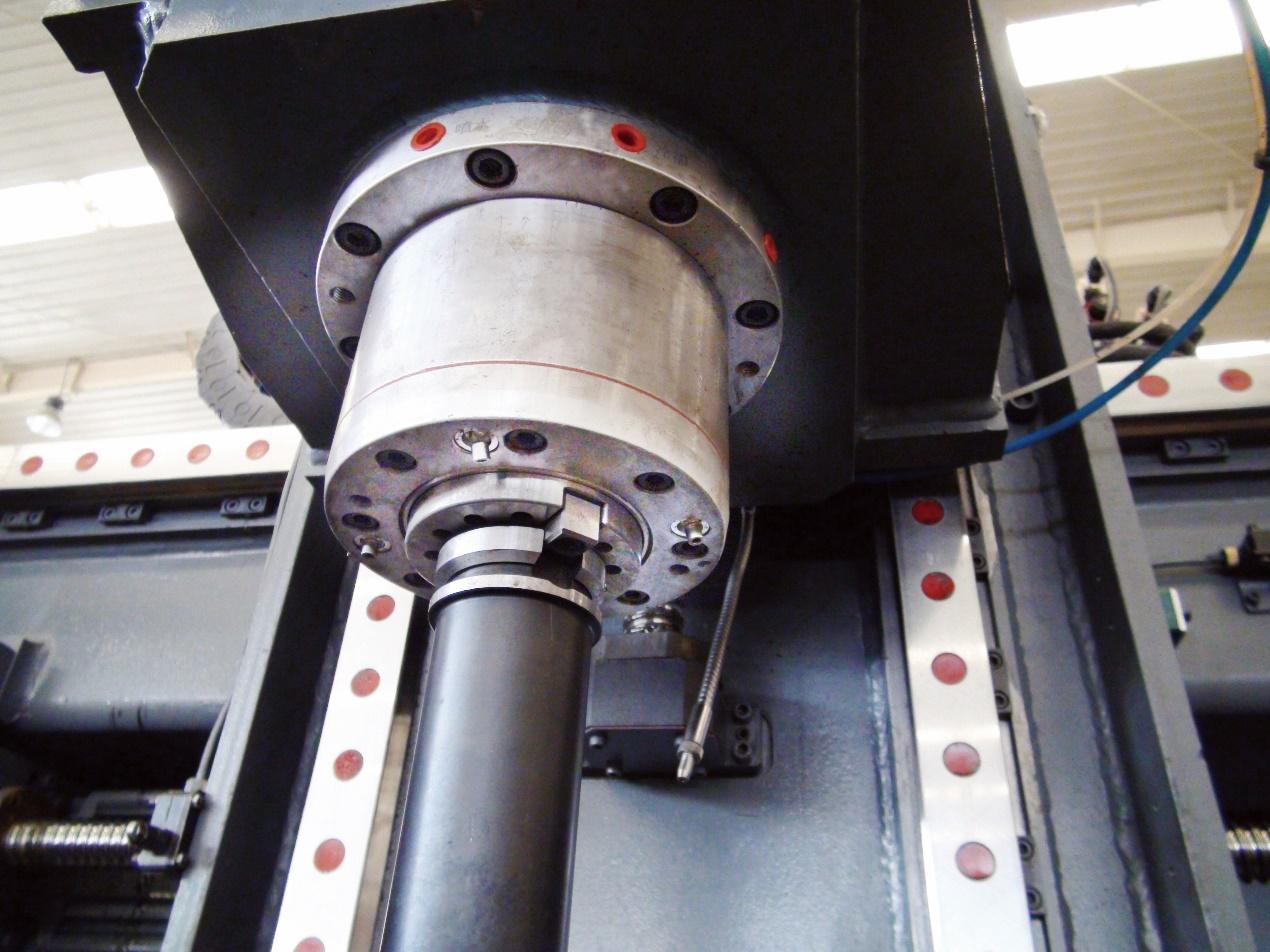

| Drilling Unit | Hollow-shaft spindles with tool clamp and internal cooling |

| Tool Cooling | Centralized coolant or optional mist spray cooling |

| Chip Evacuation | Scraper conveyor with automatic chip discharge |

| Tool Change | Manual tool change (optional ATC available) |

| Safety Systems | Emergency stop, interlocks, overload protection |

Working Environment Requirements

| Item | Requirement |

| Power Supply | 3-phase, 380V / 50Hz |

| Ambient Temperature | 0°C – 40°C |

| Humidity | ≤ 75% (non-condensing) |

| Compressed Air | 0.6–0.8 MPa, clean and dry |

| Space Requirement | Approx. 20 m × 4.5 m |

| Foundation | Reinforced concrete base recommended |

Application Scenarios

Ideal for Structural Steel, Energy & Infrastructure Projects

This high-speed drilling machine is widely used in applications such as:

Structural steel beam manufacturing for buildings, towers, and industrial plants

Prefabricated steel component factories requiring high-volume drilling

Bridge and highway girder processing with dense hole groups

Steel service centers handling mixed-profile batch production

Offshore platform and pipe rack module fabrication with precision hole layout needs

The machine meets the demands of medium to large-scale manufacturers seeking to shorten delivery times, reduce manual operations, and ensure dimensional consistency across components.

Product Media & Visuals